Noise Reduction and Epoxy Flooring: Solutions for Toronto’s Industrial Buildings

Noise Reduction & Epoxy Flooring for Industrial Spaces

📉 Hearing Damage Threshold: Exposure above 85 dB can cause hearing loss over time, and noise above 120 dB can cause immediate damage.

How Epoxy Flooring Helps Reduce Noise

Epoxy floors reduce noise levels by up to 30%, especially when paired with anti-vibration mounts and damping compounds.

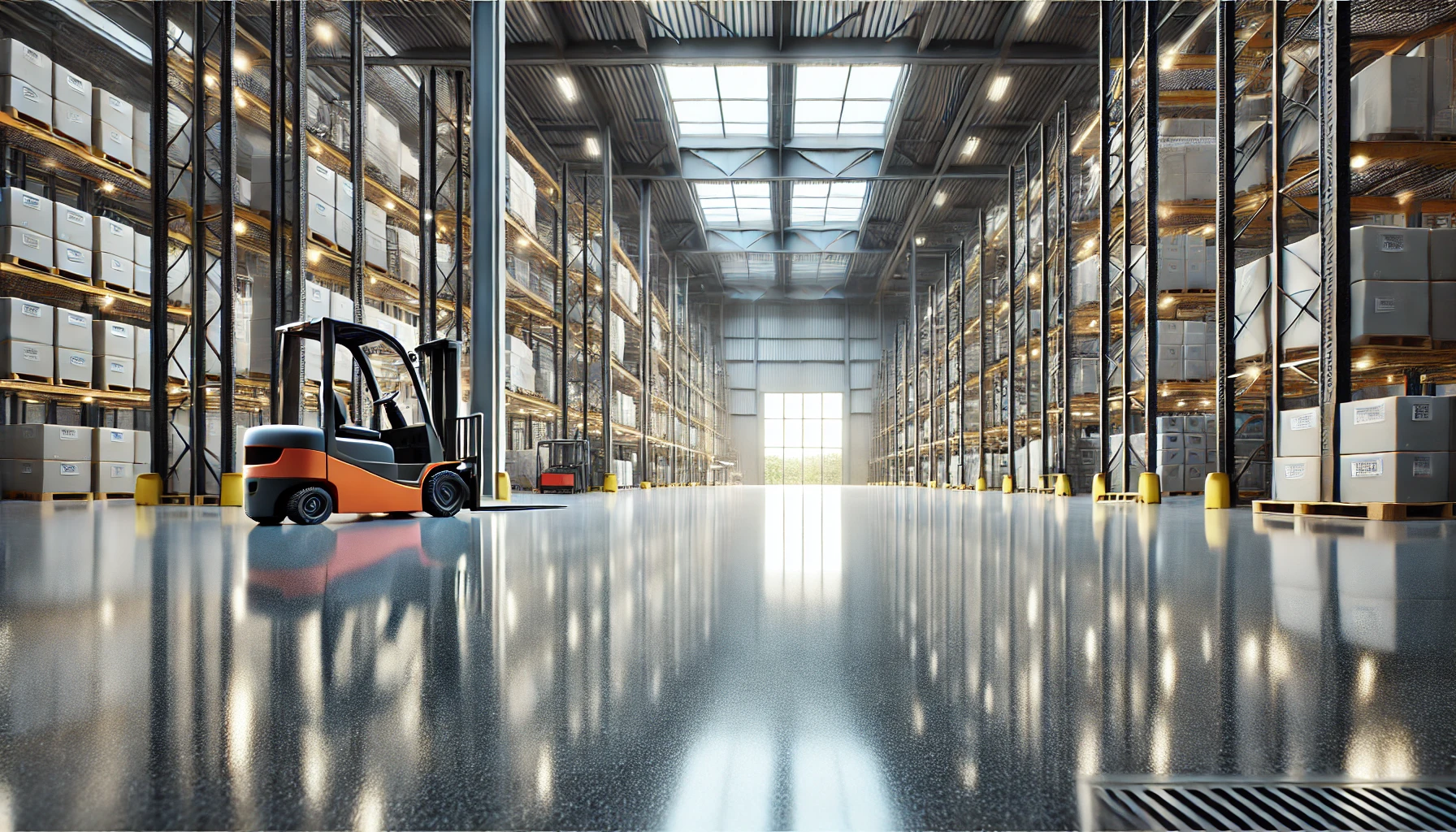

Ideal for high-noise environments, such as warehouses and manufacturing plants, making the workspace safer and more productive.

Enhanced employee focus and efficiency by reducing ambient noise and protecting against hearing loss risks.

Toronto's busy industrial landscape, noise reduction and durable flooring are critical components for maintaining a safe, efficient, and productive work environment. Industrial buildings are known for their rugged machinery and busy processes; hence noise and flooring type have been a concern. Let us begin by looking at the role played by noise control measures and industrial epoxy flooring in overcoming these challenges and improving the operational effectiveness of the industrial establishments in Toronto.

Importance of Noise Reduction

Because noise impacts employees’ welfare and productivity, noise control has become a key aspect of industrial health and safety regulations within the institution. If high noise levels persist for enough time, they can lead to hearing loss, stress, and a loss of focus on the tasks at hand.

Continuous exposure to high noise levels in industrial environments can lead to significant hearing damage. According to health and safety regulations, prolonged exposure to noise levels above 85 decibels (dB) can cause hearing loss over time. Immediate hearing damage can occur at 120 dB or higher. In industrial settings, machinery often exceeds safe noise levels, underscoring the need for effective noise reduction.

To develop a proper industrial building in Toronto with loud operations and machines, one must develop a good forest management plan. This plan includes the application of sound-dampening shields, acoustic shells or boxes, and noise-reducing technologies such as Active Noise Cancellation, Damping Councils, and Contained Layer Damping.

Types of Noise Reduction Solutions

Physical Barriers

- Sound-blocking walls and partitions

- Acoustic enclosures for machinery

- Heavy curtains and flexible barriers

Absorption Solutions

- Sound-absorbing panels and tiles

- Acoustic foam treatments

- Porous material installations

Vibration Control

- Anti-vibration mounts and pads

- Damping compounds for equipment

- Isolation systems for machinery

Active Systems

- Electronic noise cancellation

- Smart monitoring systems

- Automated noise control devices

Engineering Controls

- Equipment modifications

- Silencers and mufflers

- Low-noise machinery upgrades

When properly implemented, these solutions can reduce industrial noise by up to 30%, creating a safer and more productive work environment.

Benefits of Epoxy Flooring

Numerous advantages support using epoxy in various commercial applications. Given its resistance to heavy foot traffic, chemicals, and temperature variations, epoxy is ideal for harsh industrial environments.

Cleaning and maintaining epoxy flooring is also quite uncomplicated, eliminating the need for frequent polishing or other complex treatments. Epoxy floors are ideal for the chemical industries because they are chemically resistant and protect against stains, oil spills, and moisture.

They can improve the visual safety and quality of epoxy decorative design and relief. Additionally, epoxy flooring, which resists shock and abrasion, is beneficial to the environment and can bear weight without damage.

Epoxy flooring offers a solution by acting as a sound-dampening material. It can reduce noise levels by up to 30%, especially when combined with anti-vibration mounts and damping compounds on machinery . The smooth surface and durability of epoxy help mitigate sound transmission, especially in warehouses, factories, and heavy machinery environments. This reduction in noise not only contributes to a safer workplace but also enhances employee focus and productivity, crucial for efficient operations in Toronto’s industrial settings.

Installation and Maintenance of Epoxy Flooring

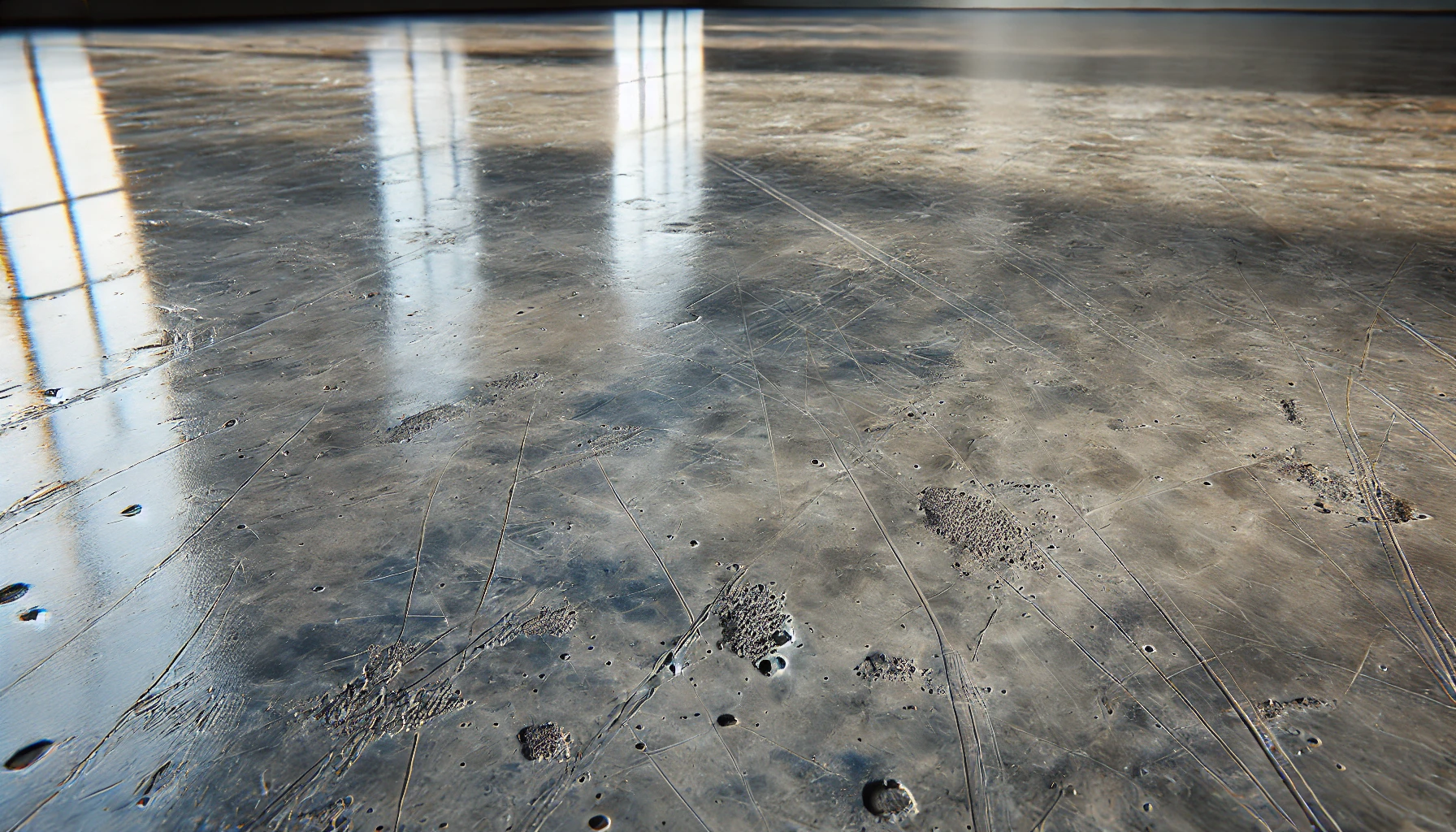

Epoxy flooring installation can be done in a simple way, but it has to be completed in an order that ensures satisfactory results. A floor is prepared for an epoxy coating because it is critical in ensuring a strong bonded joint that will last longer since this includes addressing issues such as cracks, pits and gouges and shot blasting or grinding the concrete to level the floor and remove previous coverings.

The floor still lacks the volcanic ash concrete, it has to be thoroughly sucked and wiped. Such consists of light maintenance of an office environment, such as sweeping or mopping, plus topcoats, which will probably be required once every five to seven years.

Long-term benefits are therefore assured, providing some of the requirements for qualified specialists for professional installation.

Comparison with Other Flooring Options

When it comes to lower alternate options, Epoxy Floor coatings have the advantage of a longer life span, less need for maintenance, and also cost cuts. In contrast to unsealed concrete flooring or tile flooring, epoxy floors are less prone to stains, both chemicals and moisture, and do not undergo wear and tear requiring polishing very often.

There are more safety features, such as slip-resistant properties, and more customization since epoxy floors can have safety markings. Other alternatives, such as polished concrete, do look appealing but lack the level of protection and maintenance requirements that epoxy floors can offer.

Safety and Health Implications

Experts agree on the safety and health implications of noise control and using epoxy floor coating. Noise control measures create an effective barrier against hearing loss and other health conditions such as ringing in the ear or stress. Epoxy flooring achieves increased safety in terms of slip resistance and chemical resistance to harmful substances.

Further, the ease with which epoxy floors can be disinfected is invaluable in maintaining sanitary conditions in the food and pharmaceutical industries. Companies that implement these approaches in industrial settings can sustain a positive work atmosphere, which in turn improves output.

Future Trends in Noise Reduction and Epoxy Flooring

More attention is given to new developments that promote the integration of noise control and epoxy floor coating in the future. The popularity of newer technologies, such as complete active noise canceling systems and acoustic metamaterial rings, is growing.

Improvements in nanotechnology led to the development of epoxy flooring with better absorption of sound and its echo. In recent years, there has been a noticeable trend towards using more environmental and low VOC epoxy coatings.

As industries develop further, noise control and flooring solutions will become more advanced and geared towards the needs of industrial processes.

With these solutions, facilities can preserve the health of their workers, save on maintenance costs, and enhance the overall ambience of the workplace. With the rapid advancement of technologies, new and more effective solutions will undoubtedly appear, which will make the role of noise reduction as well as epoxy flooring in the industry even more prominent.

What are the primary benefits of using epoxy flooring in industrial settings?

Some of the most common features of epoxy flooring are its high resistance to wear and chemicals, easy maintenance, and higher security with anti-slip properties. Epoxy flooring is also ideal for large, service-heavy industrial environments because it prevents stains and moisture damage.

What is the operation principle of constrained layer damping in order to reduce unwarranted sound?

This term is used when damping material is placed between two metal sheets. Because the panel bends and vibrates, this makes for a more efficient structure since it keeps the damping layer from acquiring permanent deformation as the tool oscillates, in effect increasing noise reduction levels by up to 30% compared to standard techniques.

Is it required to remove existing tiles before substrate preparation for epoxy flooring?

While it is possible to install epoxy over tile, it is not ideal. Epoxy was specifically developed for concrete surfaces, and applying it to tiles will not serve any purpose. The areas of the cove base and seams require proper preparation and application.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

We provide durable epoxy and polyaspartic flooring for garages, basements, warehouses, and commercial spaces. Serving Toronto, Vaughan, Mississauga, Markham, and beyond, we ensure fast, high-quality installations.

Epoxy Services

Contact us

Business Hours

- Mon - Sun

- -

Google Reviews

Edit Google Reviews Widget

Call

+1 647 955 6885@ 2025 All Rights Reserved || Crystal Clear Epoxy Inc