The Role of Silica Sand in Epoxy Flooring

The Role of Silica Sand in Epoxy Flooring

Silica sand enhances the **strength, durability, and slip resistance** of epoxy flooring. By reinforcing the epoxy matrix, it improves **mechanical properties**, making floors more resistant to wear and tear.

- Increased Tensile Strength: A 10% addition of silica sand boosts tensile strength from 29.47 MPa to 35.52 MPa.

- Enhanced Adhesion: Improves bonding, increasing adhesion strength from 14.21 kN to 18.79 kN.

- Slip Resistance & Texture: Varying grain sizes allow customization for safety and aesthetics.

For stronger, safer epoxy flooring, integrating silica sand is a game changer.

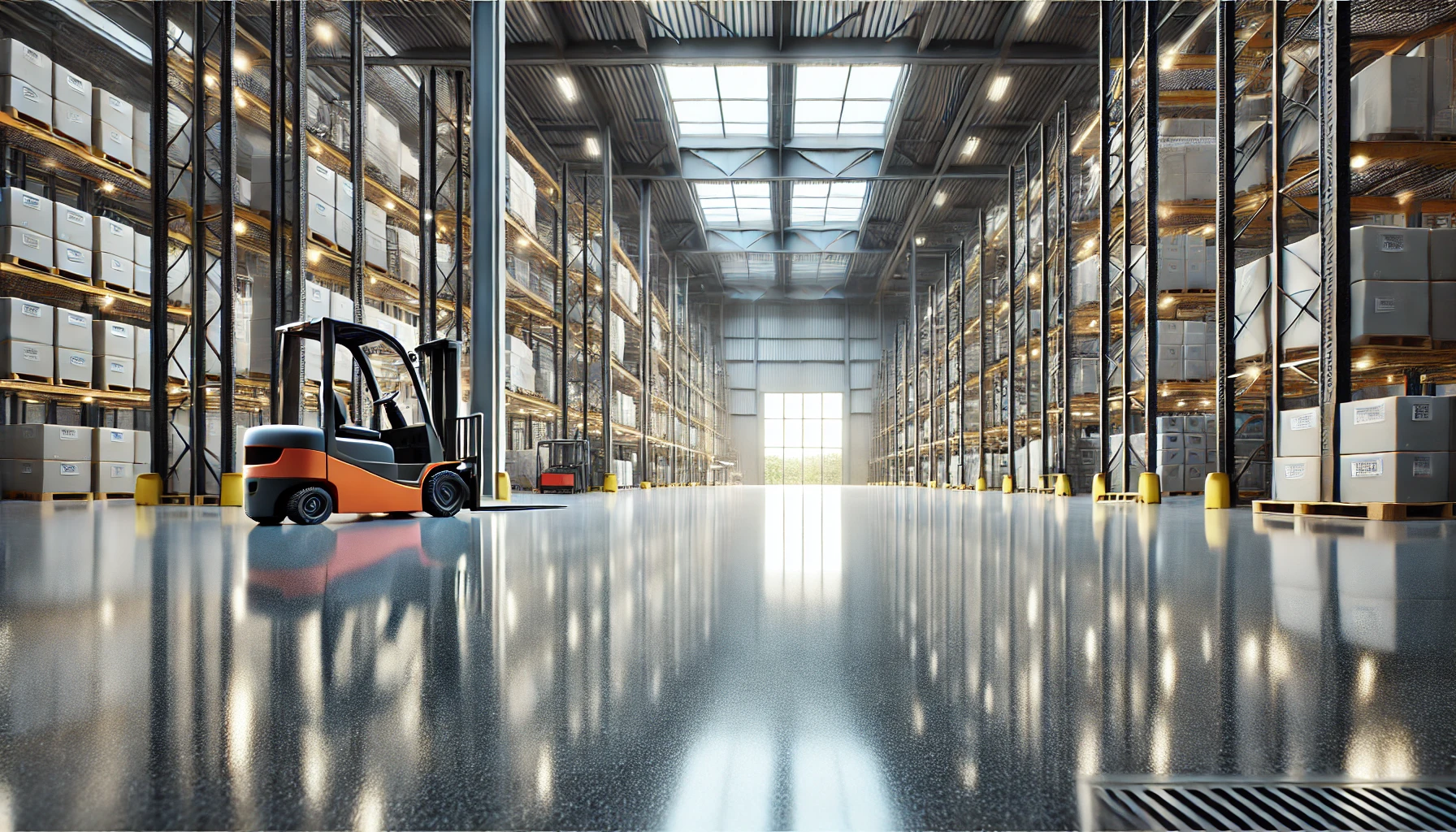

Silica sand plays a pivotal role in epoxy flooring systems, significantly enhancing their performance and durability. By understanding how silica sand improves mechanical strength, abrasion resistance, and slip resistance, and by learning the proper methods to incorporate it into epoxy coatings, you can achieve superior flooring solutions tailored to various environments.

Understanding Silica Sand in Epoxy Flooring

Silica sand, primarily composed of silicon dioxide (SiO₂), possesses several chemical and physical properties that make it an excellent additive for epoxy flooring systems. Let’s break down why it’s so effective:

Hardness & Mechanical Strength

Mohs Hardness: Silica has a Mohs hardness of 7, meaning it’s highly resistant to abrasion and wear. This makes epoxy coatings with silica sand more durable and resistant to mechanical stress, foot traffic, and industrial activity.

Silica sand is primarily composed of quartz, one of the hardest minerals on Earth. When you introduce silica sand into epoxy coatings, it acts as a reinforcing agent, enhancing the overall tensile strength and stiffness of the flooring. This means your floors become more resistant to cracking and deformation under heavy loads.

A study published in the journal Applied Sciences found that adding 10% silica sand to epoxy resin composites increased tensile strength from 29.47 MPa to 35.52 MPa and the elastic modulus from 4.38 GPa to 5.83 GPa.

Chemical Inertness

Stable & Non-Reactive: SiO₂ is chemically inert under most conditions, meaning it does not react with common chemicals, acids, or bases found in industrial environments. This makes silica sand ideal for applications in chemical-resistant flooring.

High Surface Area & Adhesion

Strong Interfacial Bonding: The high surface energy of silica sand improves adhesion between the epoxy resin matrix and the aggregate, leading to a more cohesive and reinforced structure.

Electrostatic Charge: While silica itself is not highly charged, its polar nature allows for strong intermolecular interactions with the epoxy, helping it stay embedded within the cured resin.

Thermal Stability

High Melting Point (~1,710°C or 3,110°F): Silica sand does not degrade under high temperatures, making it suitable for environments where epoxy floors may be exposed to heat.

Texture & Slip Resistance

Particle Size & Surface Roughness: The irregular surface and granular nature of silica sand improve traction in wet or high-traffic areas, reducing the risk of slips and falls.

Grit Customization: Different grit sizes allow for customized slip resistance, from fine for light traction to coarse for heavy-duty applications.

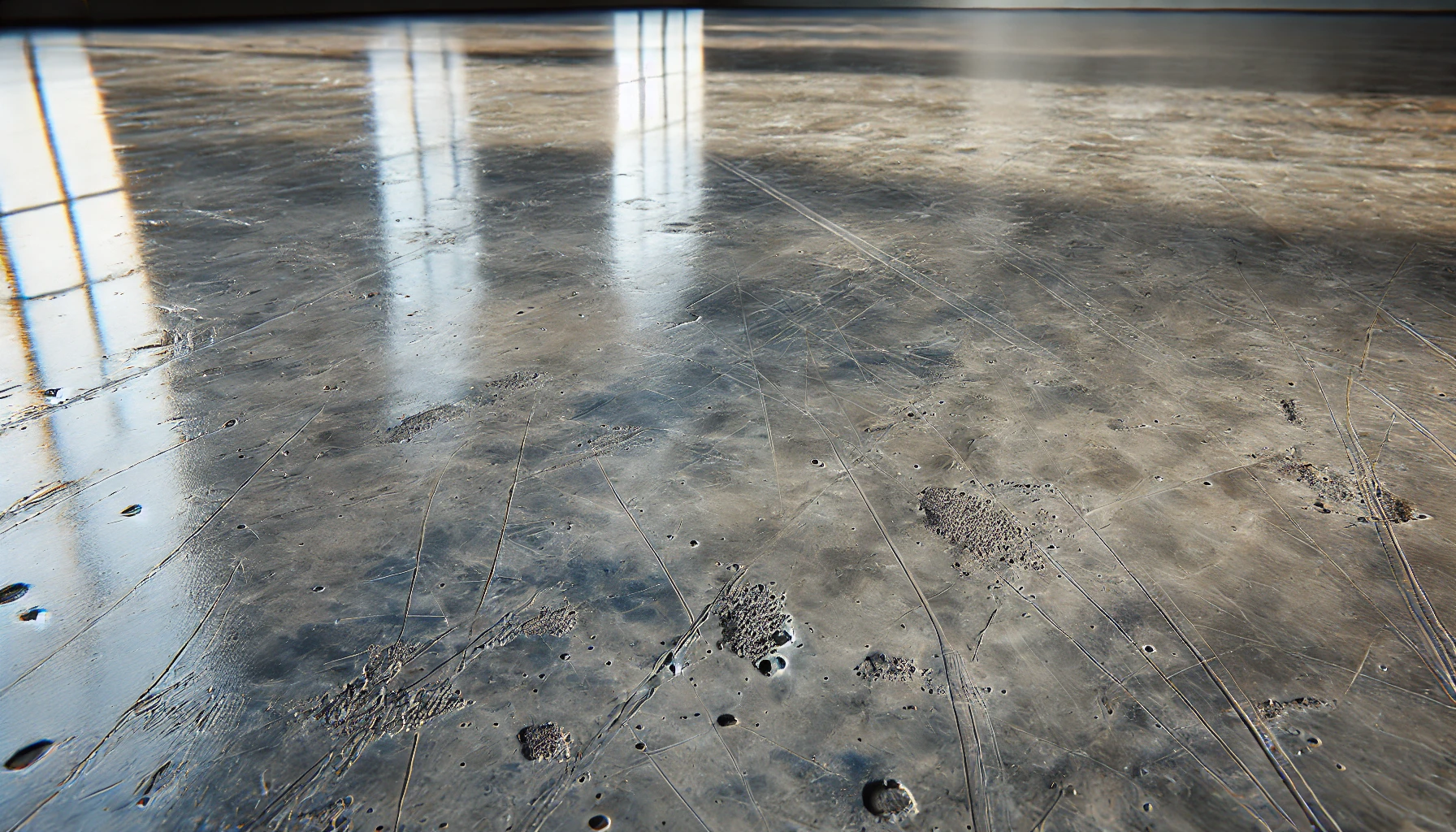

Abrasion Resistance

In high-traffic areas, floors are subjected to constant wear and tear. Silica sand's hardness provides a tough barrier against abrasion, ensuring your epoxy flooring maintains its appearance and functionality over time. The angular and rough surface texture of silica particles contributes to better interlocking within the epoxy matrix, enhancing the material's resistance to surface wear.

Filler & Load Distribution

Reinforces Epoxy Structure: Silica sand distributes mechanical loads more effectively, preventing localized stress points and reducing the likelihood of cracking or deformation.

Reduces Shrinkage: The addition of silica minimizes the shrinkage of epoxy during curing, leading to a more dimensionally stable flooring system.

Why Not Other Additives?

Compared to

calcium carbonate (CaCO₃) or

aluminum oxide (Al₂O₃), silica sand is

more cost-effective, widely available, and provides an excellent balance between

strength, durability, and cost.

Types of Silica Sand: Round vs. Angular Grains

The shape of silica sand grains plays a crucial role in determining the texture and slip resistance of the epoxy flooring.

- Round Grains: These grains offer a smoother finish, which may be desirable in settings where ease of cleaning is a priority. However, they provide less traction compared to angular grains, making them less suitable for areas where slip resistance is critical.

- Angular Grains: Angular silica sand grains create a more textured surface, enhancing slip resistance. This makes them ideal for environments where safety is a concern, such as industrial kitchens or wet processing areas.

Grain Sizes and Their Impact on Slip Resistance

The size of the silica sand grains also affects the texture and slip resistance of the epoxy flooring.

- Fine Grains: Finer silica sand particles result in a smoother surface with moderate slip resistance. This is suitable for areas where a balance between aesthetics and safety is desired.

- Coarse Grains: Larger grains create a rougher texture, significantly enhancing slip resistance. This is particularly beneficial in environments prone to moisture or where heavy-duty slip resistance is required.

Proper Mixing Techniques: Ensuring Optimal Performance

Incorporating silica sand into epoxy coatings requires meticulous attention to mixing techniques to ensure that the desired properties are achieved without compromising the coating's adhesion or flow characteristics.

1. Selecting the Appropriate Silica Sand

Choose silica sand that matches the desired outcome for your flooring system. Consider factors such as grain shape, size, and purity. High-purity silica sand is preferred to avoid any adverse reactions with the epoxy resin.

2. Determining the Correct Mixing Ratio

The ratio of silica sand to epoxy resin is crucial. An optimal balance ensures enhanced mechanical properties without affecting the coating's workability. It's advisable to follow manufacturer recommendations or consult with flooring specialists to determine the appropriate mixing ratio for your specific application.

3. Mixing Procedure

- Preparation: Ensure that all materials, including the epoxy resin, hardener, and silica sand, are at the recommended temperatures. This facilitates proper mixing and curing.

- Initial Mixing: Combine the epoxy resin and hardener as per the manufacturer's instructions. Mix thoroughly to achieve a uniform blend.

- Incorporating Silica Sand: Gradually add the silica sand to the mixed epoxy, stirring continuously to ensure even distribution. Avoid adding too much sand at once, as this can lead to clumping and uneven texture.

- Consistency Check: After adding the silica sand, assess the mixture's consistency. It should be workable and not too thick to apply smoothly.

4. Application

Apply the silica sand-infused epoxy mixture to the prepared substrate using appropriate tools, such as trowels or rollers. Ensure even application to achieve a consistent finish and performance across the entire surface.

5. Curing

Allow the epoxy flooring to cure as per the manufacturer's guidelines. Proper curing is essential to achieve the desired mechanical properties and durability.

Benefits of Using Silica Sand in Epoxy Flooring

Integrating silica sand into epoxy flooring systems offers numerous advantages that enhance both the functionality and longevity of the flooring.

1. Improved Durability

The addition of silica sand significantly enhances the flooring's ability to withstand mechanical stresses, making it suitable for environments subjected to heavy foot traffic, machinery, and equipment.

2. Enhanced Slip Resistance

By selecting the appropriate grain shape and size, silica sand can be used to tailor the slip resistance of the flooring. This is particularly important in areas where safety is a concern, such as wet processing zones or commercial kitchens.

3. Cost-Effectiveness

The increased durability and reduced maintenance needs resulting from the incorporation of silica sand can lead to cost savings over the flooring's lifespan.

4. Aesthetic Versatility

Silica sand can be combined with colored quartz or other decorative aggregates to create visually appealing flooring designs without compromising performance.

The Impact of Silica Sand on Epoxy Flooring

To quantify the benefits of incorporating silica sand into epoxy flooring, let's examine some key statistics:

| Property | Without Silica Sand | With 10% Silica Sand Addition |

|---|---|---|

| Tensile Strength (MPa) | 29.47 | 35.52 |

| Elastic Modulus (GPa) | 4.38 | 5.83 |

| Adhesion Strength (kN) | 14.21 | 18.79 |

These figures demonstrate that a 10% addition of silica sand can significantly enhance the mechanical properties of epoxy resin, leading to stronger and more durable flooring systems.

Incorporating silica sand into epoxy flooring systems is a strategic approach to enhancing durability, safety, and overall performance. By selecting the appropriate type and size of silica sand and employing proper mixing techniques, you can tailor the flooring to meet specific requirements, ensuring longevity and functionality.

For professional epoxy flooring services that leverage the benefits of silica sand, consider reaching out to us at Crystal Clear Epoxy Inc.. Our expertise in delivering high-quality epoxy floors can help you achieve a solution tailored to your specific needs.

Frequently Asked Questions

Can adding too much silica sand affect the epoxy coating?

Yes, adding excessive silica sand can thicken the mixture, making application difficult and potentially creating weak spots in the flooring. It's essential to follow recommended mixing ratios to maintain the coating's integrity.

Is silica sand suitable for all epoxy flooring applications?

While silica sand enhances durability and slip resistance, its suitability depends on the specific requirements of the environment. For instance, areas needing a smoother finish may opt for round grains, while industrial settings requiring high slip resistance might choose angular grains.

How does the addition of silica sand impact the aesthetic appearance of epoxy floors?

Silica sand can be combined with colored quartz or other decorative aggregates to create visually appealing designs without compromising performance. The choice of grain shape and size also influences the floor's texture and overall look.

What are the cost implications of using silica sand in epoxy flooring?

Integrating silica sand can lead to cost savings over the flooring's lifespan due to increased durability and reduced maintenance needs. However, initial costs may vary based on the quality and type of silica sand used.