Why Epoxy Flooring is Perfect for Warehouses and Manufacturing Facilities

Why Epoxy Flooring is Ideal for Warehouses

Epoxy flooring offers unmatched durability, resistance to wear and tear, and a sleek, professional appearance. Perfect for high-traffic areas, it withstands heavy machinery, chemical spills, and frequent cleaning, ensuring a long-lasting and cost-effective solution.

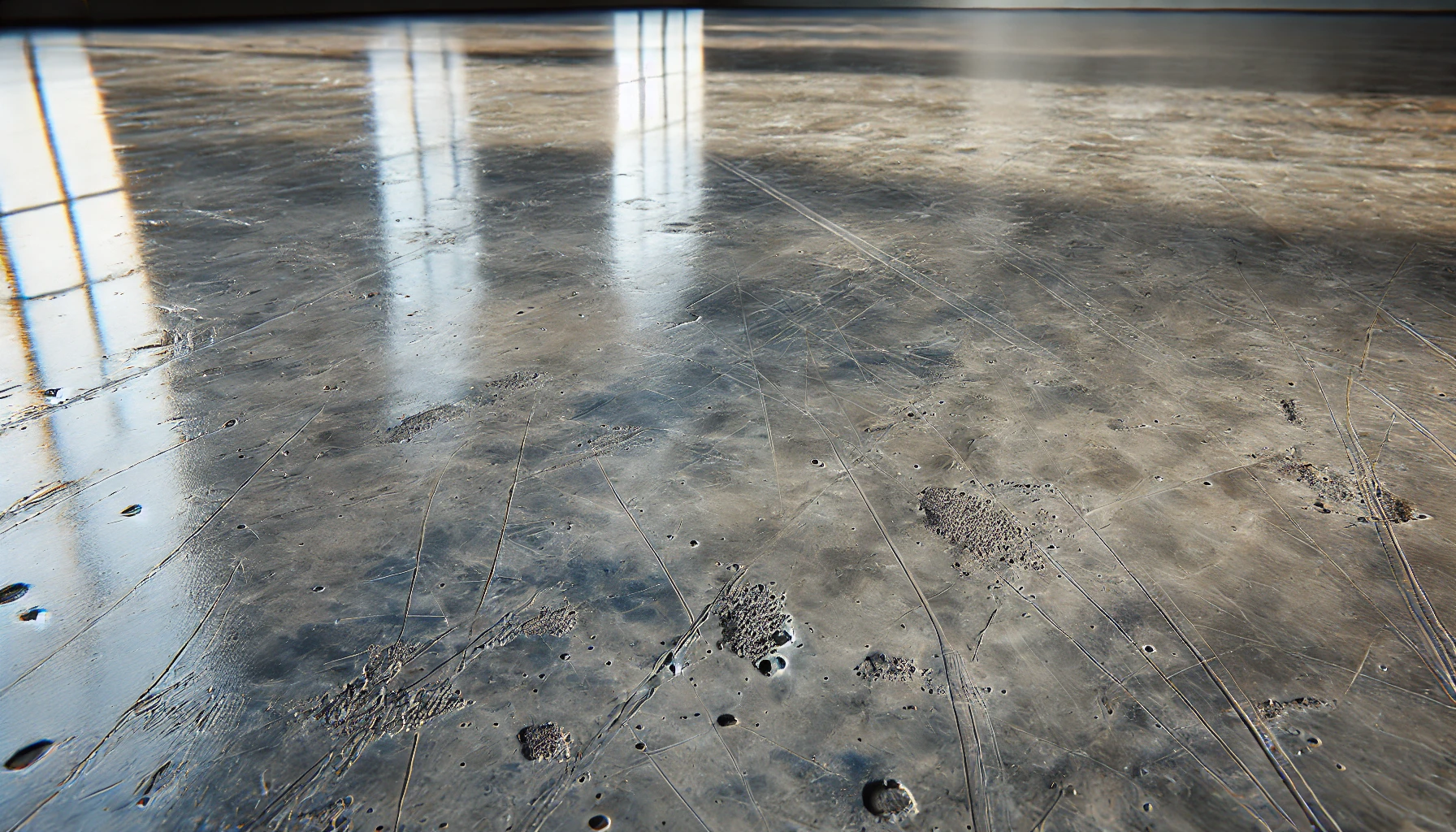

A warehouse or a manufacturing site has heavy vehicular and machinery traffic, thus requiring durable and low-maintenance flooring. It is unsurprising to see epoxy flooring relocating to the top of the market owing to its superior performance and economic advantages. Once applied, an epoxy coating forms an aggressive bond on concrete surfaces to produce a shiny monolithic surface that is aesthetically appealing and chemical, stain, and impact resistant. This toughness makes it the most suitable choice for busy workplaces where cleanliness and safety are the foremost concerns. In addition, epoxy flooring is low maintenance, which will, in the long run, benefit the firms and save them a lot of time and finances. With this in mind, let us see how epoxy flooring can help your facility look aesthetically appealing.

Easy Installation Process for Epoxy Flooring

Apart from the cost-effectiveness of epoxy floors, other advantages include the simplicity of installing the epoxy, which allows it to be placed over a concrete surface without causing any interruptions. Epoxy adhesives are pressed into the ground before mixing with the resin as part of the installation process.

Primers, acrylics, and adhesives are all used as adhesives in conjunction with the resin mixture. Resin is commonly used as a lacquer because it can withstand extreme temperatures. Epoxy Flooring can be cleaned with a mop when necessary.

Repairs can also be made using a trowel or concrete tool to fill in cracks. Any production plant or facility can meet the required lead times by ensuring minimal disruption to day-to-day operations at any given time.

Long-Lasting Solution for High-Traffic Areas

As warehouses and manufacturing areas have hardwearing requirements, so do their floors. Constantly being battered by heavy machinery, forklifts moving across the floor, and human foot traffic means most standard epoxy floor finishes will only last for a while before considerably wearing down.

Fortunately, epoxy may be applied to resist the appearance of wear consistent with those conditions. Epoxy's unique properties are due to its chemical makeup, which makes it a tough, hard floor finish impervious to scratches, abrasions, and impact.

Epoxy may be the ideal floor finish because it doesn't chip or crack. The real bonus for business owners is the longevity of their floor and, therefore, reduced maintenance costs. Applying epoxy in areas with a lot of activity and creating a custom-made finish with slip-resistant properties is also possible.

Resistance to Chemical Spills and Stains

Epoxy flooring is also highly resistant to chemical spills and stains, making it suitable for use in warehouses and manufacturing facilities. Floors resistant to polymers, oils, and other harsh industrial materials are essential in industries where these materials are used.

Thanks to the epoxy floor coating's non-porous character, the surface acts as a protective layer, preventing liquids from penetrating and causing structural instability. This resistance helps protect the floors and promotes a safe and hygienic workplace.

Companies spend less time and money on complex and expensive repairs and maintenance work, thereby enabling timely sales services. In addition, stained surfaces are not pleasing to look at and picture, which is necessary for companies trying to project a specific professional image.

Attractive designs and color options are available.

- Variety of Colour Selections: Epoxy flooring comes in many colors, both bold and plain, and there is room for adjustment to completely fit in with a company's color branding or the particular needs of the furniture in the room. This diversity, however, makes it practical and hard-wearing for several uses and boasts a pleasing appearance that can improve the setting as a whole.

- Choices of Patterns and Textures: Epoxy flooring can come in different color options, but this does not mean that it is the end of the design options, as it can also be layered with other aesthetic elements, such as different types of textures and patterns. If you do not like smooth surfaces and emphasize intricate details, then epoxy covering suits any taste because of its many finishing styles. This diversity in the room gives it a fresh touch.

- Designating Working Boundaries: Epoxy flooring's unique feature of utilizing various colors and patterns allows companies to implement graffiti quickly when defining multiple offices within one space. This feature can easily promote organization and safety issues, flushing different activities from each other for improved work management procedures.

- High Gloss Finish: An astounding feature of the stylish epoxy floor is the high gloss finish, which helps it look more appealing and provides functional value in the way that it adequately reflects light. This glare can help the area look more comfortable, reducing how many lights are required in the room and thereby helping with energy consumption.

- Increased Property Value: We, as consumers, can further improve the general impression of the facility by making a good choice and installing good-looking and quality epoxy flooring. Besides providing the facility with a better appearance, this improvement can help boost the property's market value, making it more appealing to potential buyers or renters, which is an excellent form of investment in the long run.

Cost Benefits of Choosing Epoxy Flooring

There are a lot of economic benefits to using epoxy flooring in your facility, which is why many companies prefer it. One of the most tangible economic advantages is its ability to withstand wear and tear, thus decreasing the pressure to repair or change it constantly.

Unlike some conventional floor finishes, epoxy'sepoxy's structural reliability allows it to endure high traffic levels and damage for extended periods, resulting in lower maintenance costs in the long run. In addition, there is also a minimal economic impact from business interruption since epoxy floors take little time to apply.

Factors such as ease of cleaning and maintenance also make these floors economically favorable. Being non-porous, the surfaces do not require excessive work and resources to keep the workplace clean.

Simple Cleaning and Maintenance Procedures

Another advantage of epoxy floors is that they do not require much effort in cleaning, something that most business proprietors wish to have as it minimizes the time spent on such activities. The floor does not absorb moisture, which means that dust, dirt, dried spills, and other messes can be practically swept off using a mop, broom, and vacuum cleaner. Floors can also be mopped or swabbed to help avoid any potential accumulations.

A mop with cleaning soap or mild detergent will also occasionally clean the floors. There is no need to have costly specialty products to maintain such epoxy floors; rather, simple and cheap fixings will be as effective as the above-mentioned practices. As such, stain-resistant sappiness, tough stains, and spills can easily be wiped off, simplifying the entire cleaning process and thus enhancing efficiency in cleaning the places.

Environmental Benefits of Using Epoxy Materials

Epoxy flooring is a wise choice because of its functional and visual benefits and its merits in protecting the environment. One of the characteristics of epoxy materials is their longevity, which means infrequent replacements, which in turn pollute the ecosystem. This durable linkage shrinks material consumption within a period as the substitutes are reduced.

Besides, the epoxy surface eliminates the need for constant updating because of its high resistance to adverse environmental conditions. When epoxy floors are installed, the amount of maintenance and many other resources required is less. Also, since the epoxy is smooth and non-porous, it is inert to bacterial and mold infestation and requires fewer harmful chemical cleaning agents to maintain the indoor environment.

Frequently Asked Questions

How long does epoxy flooring ordinarily last?

When epoxy flooring durability is questioned, there is a sense of great assurance. It can last about 10 to 20 years when properly installed and maintained, especially in residential places. In industrial settings or environments with frequent foot traffic, its longevity can vary, but moderate maintenance can go a long way to preserving it. Due to the extraordinary capabilities of the coating system, it requires a one-time investment that pays off greatly in the long run.

Can epoxy flooring be used outside?

Because of its excellent chemical and high-impact resistance, epoxy flooring is predominantly used indoors, but there is no reason it can't be utilized outside as well. Just remember to use UV-stabilized epoxies so that the coating does not become yellow or fade from UV light when used outside. The finishes also have a slip-resistant property, which makes them great for driveways or patios.

Can epoxy flooring be put on top of tiles?

In many cases, the answer is yes. However, the surface needs to be prepped first before it can be done. The surface must be cleaned and etched, and cracks or other deterioration must be fixed beforehand to ensure maximum epoxy bonding strength. Further consultation regarding the bonding to the floor will help determine the best approach to achieving seamless results for the existing floor surface.

From its high resilience and visuals to its sustainability, epoxy flooring is among the best all-around solutions for minimal investment. Besides improving operational efficiency, lowering maintenance requirements, and increasing the useful life of your flooring, it also helps achieve sustainability objectives. Whether it is enhancing the look of a space, increasing the value of a property, or reducing maintenance costs, installing epoxy floors goes the extra mile in IT investment. Adopting epoxy also promotes a clean and efficient environment while keeping your space beautiful for many years without any effort.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

We provide durable epoxy and polyaspartic flooring for garages, basements, warehouses, and commercial spaces. Serving Toronto, Vaughan, Mississauga, Markham, and beyond, we ensure fast, high-quality installations.

Epoxy Services

Contact us

Business Hours

- Mon - Sun

- -

Google Reviews

Edit Google Reviews Widget

Call

+1 647 955 6885@ 2025 All Rights Reserved || Crystal Clear Epoxy Inc