Why Urico, MPC, and Pure Epoxy Set the Standard for Food Labs and Factories

Why Urico, MPC, and Pure Epoxy Lead the Industry

Looking for the gold standard in food-grade and industrial flooring?

Urico, MPC, and Pure Epoxy outperform Sherwin-Williams, Sika, and Stonhard in key areas like:

- ✅ Moisture mitigation & thermal shock resistance

- ✅ Faster installation with minimal downtime

- ✅ Superior chemical & slip resistance

- ✅ FDA, USDA, and CFIA compliance

Whether you're running a food lab, a factory, or a clean room, these systems deliver unmatched performance, durability, and safety.

When it comes to food labs and industrial factories, flooring isn’t just about aesthetics. Your flooring must be durable, chemical-resistant, non-slip, and compliant with strict safety standards. A weak or poorly chosen floor can lead to costly repairs, regulatory violations, and safety hazards.

That’s why Urico, MPC, and Pure Epoxy are the gold standard for food-grade flooring. They outperform competitors like Sherwin-Williams, Sika, and Stonhard in durability, hygiene, safety, and long-term cost savings.

In this in-depth comparison, you’ll see exactly why Urico, MPC, and Pure Epoxy dominate the market.

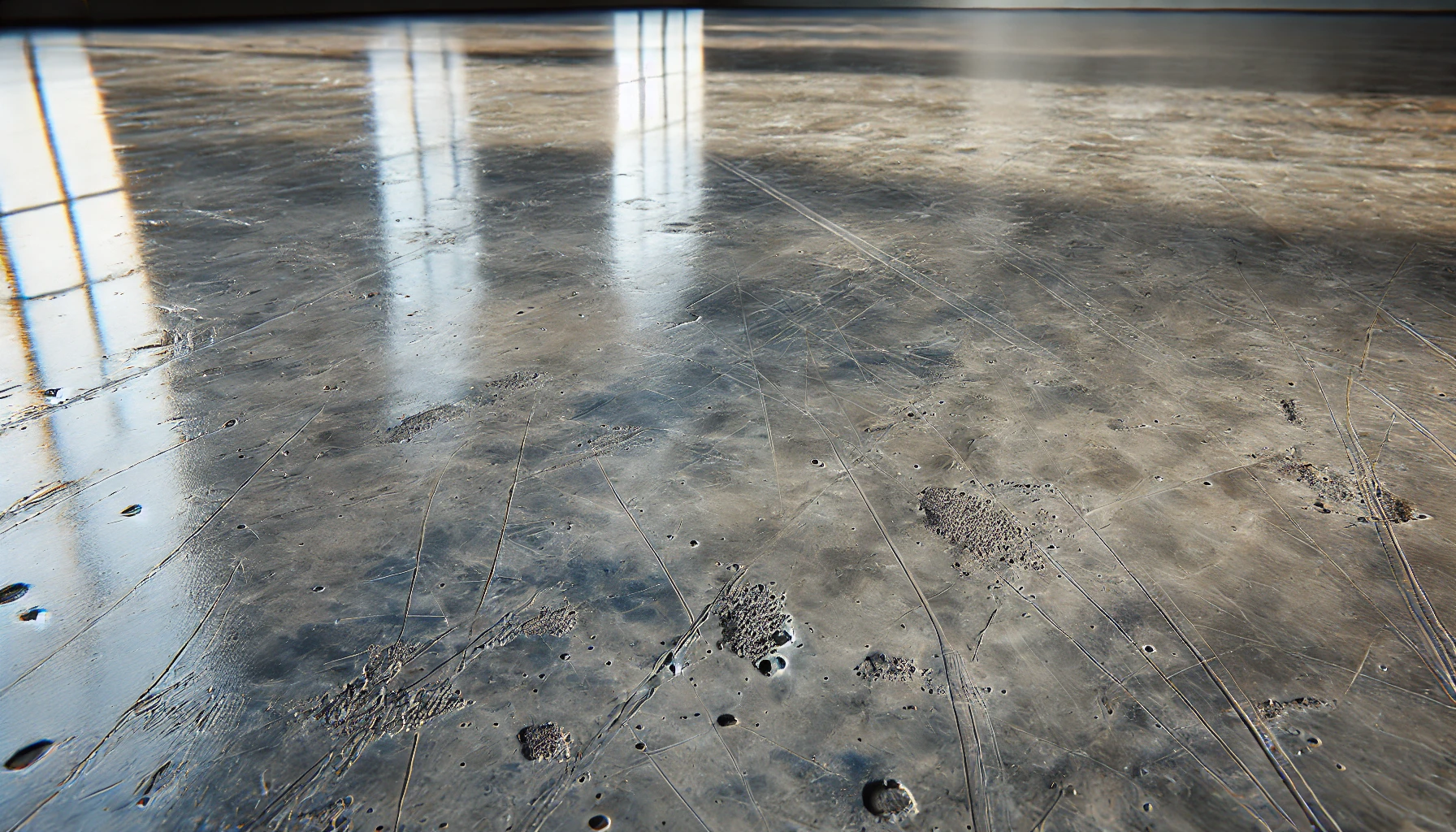

Challenges of Flooring in Food and Industrial Facilities

Before diving into product comparisons, let’s discuss what your floors must withstand in these high-stakes environments.

1. Thermal Shock Resistance

Food processing plants and factories experience extreme temperature fluctuations. Your flooring needs to withstand sudden exposure to boiling liquids, freezing conditions, and steam cleaning without cracking or delaminating.

2. Chemical & Stain Resistance

Cleaning solutions, acids, alkalis, and other chemicals break down inferior coatings over time. A truly food-safe floor must be impervious to aggressive cleaning agents and contaminants.

3. Moisture & Slip Resistance

Slips and falls are among the leading causes of workplace injuries. Your flooring must remain non-slip, even in wet conditions. It should also resist moisture absorption, which can lead to bacterial growth and safety violations.

4. FDA, USDA, and CFIA Compliance

Food facilities must adhere to stringent health codes and regulations. Using non-compliant flooring could result in fines, shutdowns, or product contamination.

5. Fast Installation & Minimal Downtime

The longer it takes to install or repair your flooring, the longer your operations are disrupted. Quick installation and minimal curing time are crucial to avoid profit loss.

Now, let’s see how Urico, MPC, and Pure Epoxy solve these challenges better than Sherwin-Williams, Sika, and Stonhard.

Urico - The Ultimate Urethane Cement System

Urico urethane cement is specifically designed for food-grade and heavy industrial flooring applications. You need a flooring solution that can handle extreme conditions, and Urico delivers with superior resistance to thermal shock, chemicals, and moisture.

Key Specifications

- Thermal Shock Resistance: Withstands extreme temperature shifts from -40°C to 120°C, making it ideal for food labs, breweries, and commercial kitchens.

- Chemical Resistance: Resists acids, alkalis, and sanitizing agents used in food processing plants.

- Moisture Tolerance: Can be applied to damp substrates, reducing downtime and installation delays.

- Slip Resistance: Available in multiple textures to meet safety requirements for high-traffic zones.

- Fast Cure Times: Reduces downtime for operational facilities, making it more efficient than traditional epoxy systems.

| Feature | Urico | Stonhard (Stonclad UT) | Sika (Sikafloor 22NA PurCem) | Sherwin-Williams (FasTop Urethane Slurry) |

|---|---|---|---|---|

| Moisture Mitigation | Superior | Moderate | Moderate | Moderate |

| Customizable Slip Resistance | Yes | Limited | Yes | Limited |

| Cure Time | Faster | Standard | Standard | Slower |

| Temperature Resistance | -40°C to 120°C | -29°C to 93°C | -30°C to 110°C | -34°C to 100°C |

Best for: Food processing plants, breweries, pharmaceutical labs, and chemical processing facilities.

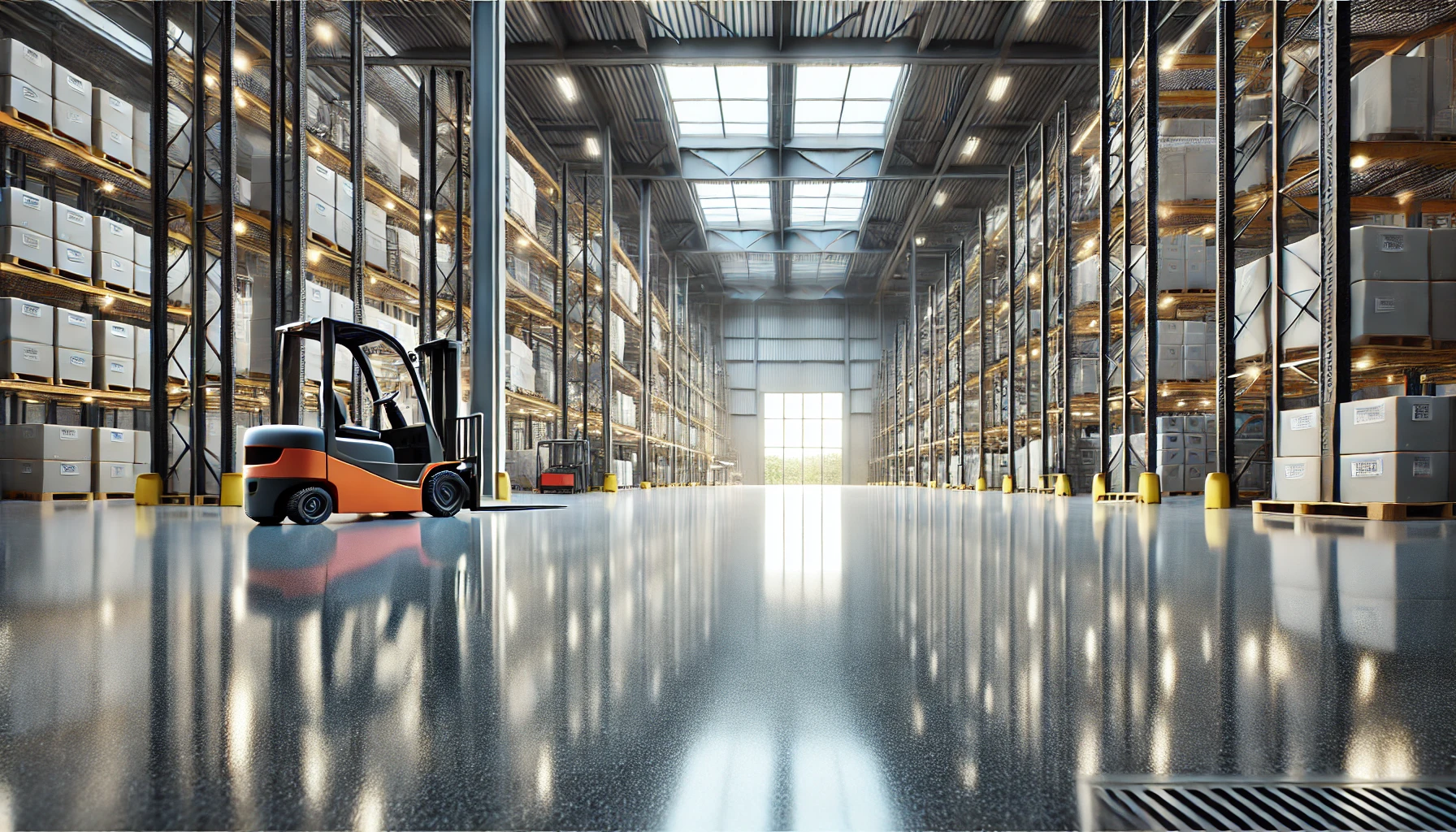

MPC - The Workhorse of Industrial Epoxy Flooring

MPC (Master Protective Coatings) provides heavy-duty, high-performance epoxy coatings that withstand intense mechanical wear, chemicals, and impact. If you need an industrial flooring system that lasts, MPC is the solution.

Key Specifications:

- 100% Solids Epoxy: Ensures a seamless, impermeable surface that resists staining and bacterial growth.

- Self-Leveling Formula: Ideal for facilities needing a smooth, level surface with minimal application effort.

- Exceptional Bond Strength: Creates a robust, durable floor with a high compressive strength of 10,000+ psi.

- UV Stability: Available with polyaspartic topcoats to maintain color and gloss over time.

- FDA & USDA Compliance: Meets food safety regulations for direct and indirect food contact areas.

| Feature | MPC | Sherwin-Williams (ArmorSeal 1000 HS) | Sika (Sikafloor 510 N LPL) | Stonhard (Stonshield) |

|---|---|---|---|---|

| Bond Strength | 10,000+ psi | 7,000 psi | 8,000 psi | 7,500 psi |

| Abrasion Resistance | Excellent | Moderate | Good | Moderate |

| Installation Time | Fast | Standard | Slow | Slow |

| VOC Levels | Low | High | High | Moderate |

Best for: Manufacturing plants, warehouses, automotive shops, and commercial kitchens.

Pure Epoxy - The Ultimate in Clarity and Chemical Resistance

Pure Epoxy is engineered for maximum chemical resistance, clarity, and ease of maintenance, making it the ideal choice for laboratories, pharmaceutical plants, and clean rooms.

Key Specifications:

- High Gloss & Clarity: Provides a crystal-clear finish with exceptional UV stability.

- Ultra Chemical-Resistant Formula: Resists acids, solvents, and disinfectants, ensuring longevity in sterile environments.

- Fast Cure Time: Accelerates installation and reduces downtime.

- Non-Yellowing: Maintains its original appearance even under harsh lighting and cleaning conditions.

- VOC-Free & Low Odor: Ensures safer installation and indoor air quality.

| Feature | Pure Epoxy | Sherwin-Williams (Resutile HTS 100) | Sika (Sikafloor 305 W) | Stonhard (Stonblend GSI-G) |

|---|---|---|---|---|

| UV Resistance | Excellent | Good | Moderate | Moderate |

| Chemical Resistance | Superior | Good | Good | Moderate |

| Installation Complexity | Easy | Moderate | Complex | Complex |

| Customization Options | High | Low | Low | Moderate |

Best for: Laboratories, pharmaceutical plants, clean rooms, hospitals, and high-tech manufacturing.

Real-World Applications & Customer Testimonials

- Food Processing Plant (Mississauga, ON): A major food lab needed a flooring solution that could withstand daily chemical cleaning. After switching to Urico, the facility reported a 45% reduction in maintenance costs and improved compliance with FDA regulations.

- Pharmaceutical Lab (Toronto, ON): A clean room installation with Pure Epoxy led to a 30% improvement in contamination control compared to their previous flooring system.

- Automotive Facility (North York, ON): A warehouse using MPC epoxy flooring saw a 50% increase in floor durability, reducing replacement costs.

Why Choose Crystal Clear Epoxy?

When selecting flooring solutions for food labs, industrial plants, and commercial facilities, Urico, MPC, and Pure Epoxy stand above the rest. Compared to competitors like Sherwin-Williams, Sika, and Stonhard, they offer superior durability, faster installation, stronger chemical resistance, and lower maintenance costs.

At

Crystal Clear Epoxy, you get more than just epoxy—we provide the

gold standard in industrial flooring.

Frequently Asked Questions

How does Urico compare to traditional epoxy flooring?

Urico urethane cement outperforms traditional epoxy in thermal shock resistance, chemical resistance, and moisture tolerance. It is ideal for food processing plants, breweries, and commercial kitchens where extreme temperatures and heavy sanitation are common.

Is MPC epoxy safe for food contact areas?

Yes, MPC epoxy is FDA and USDA compliant, making it safe for use in food contact areas. Its seamless, non-porous surface prevents bacteria buildup and ensures easy cleaning.

What makes Pure Epoxy a good choice for laboratories and clean rooms?

Pure Epoxy offers high chemical resistance, a non-yellowing crystal-clear finish, and low VOC emissions. It is ideal for sterile environments where maintaining a pristine, contamination-free surface is essential.

How long does it take for these epoxy systems to cure?

Cure times vary depending on the product and environmental conditions. Urico cures faster than most competitors, reducing downtime. MPC and Pure Epoxy also have rapid cure options for facilities needing a quick turnaround.

How do these epoxy systems compare to Sherwin-Williams, Sika, and Stonhard?

Urico, MPC, and Pure Epoxy offer superior durability, chemical resistance, and faster installation compared to Sherwin-Williams, Sika, and Stonhard. They also provide more customizable finishes, better moisture tolerance, and improved long-term performance.

Can these flooring systems handle heavy machinery and forklifts?

Yes, all three systems—Urico, MPC, and Pure Epoxy—are designed to handle heavy loads, high-impact areas, and constant machinery movement without cracking or wearing down.