UV Stability in Epoxy: Why Some Floors Yellow While Others Stay Crystal Clear

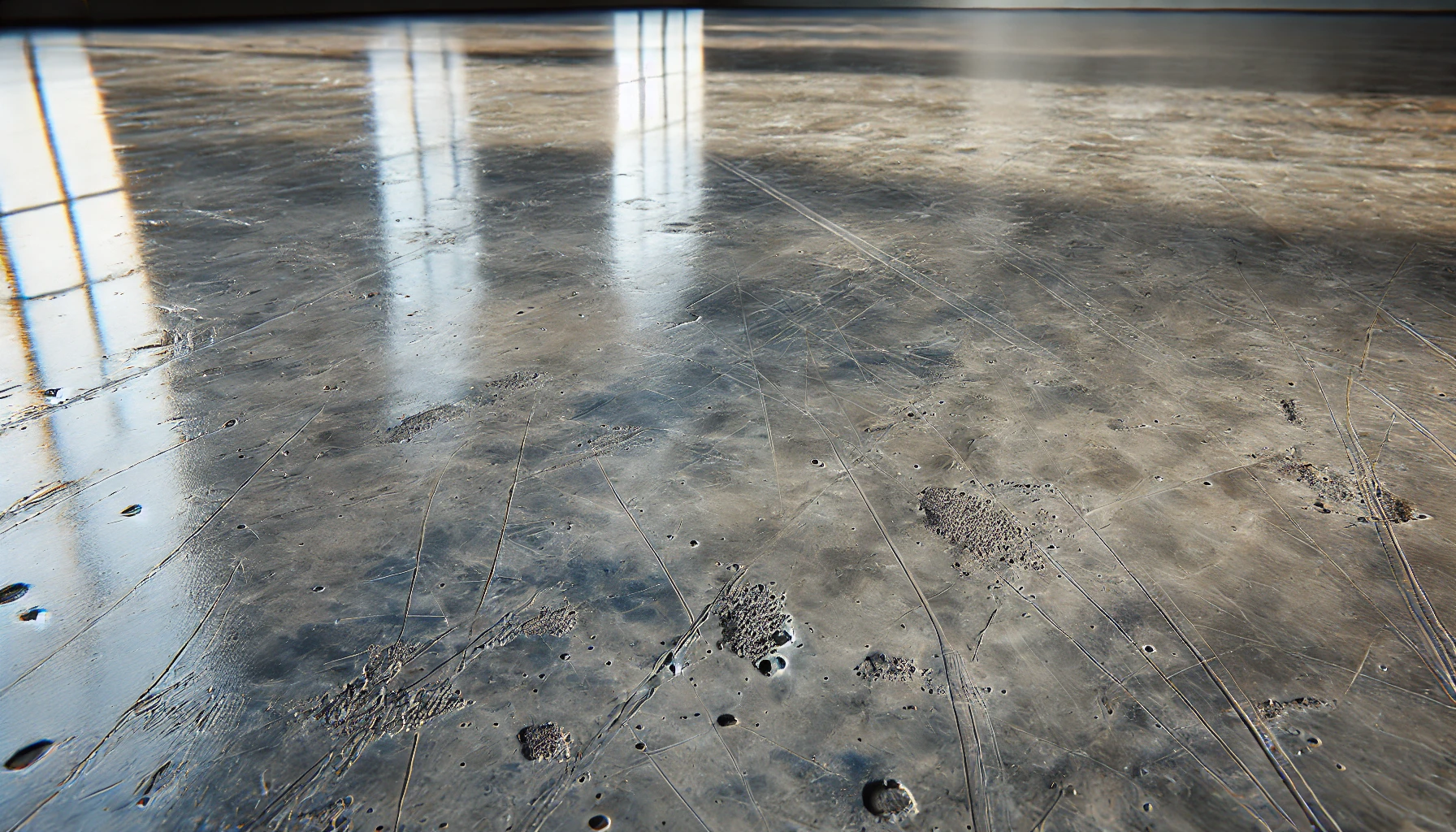

Epoxy flooring is popular for its durability and glossy finish. But have you ever noticed some epoxy floors turn yellow over time while others remain crystal clear? The reason comes down to UV stability in epoxy.

Not all epoxy formulations are the same. Some break down under UV exposure, leading to discoloration. Others use advanced chemistry and topcoat technology to resist yellowing. Understanding aliphatic vs. aromatic formulations is key to choosing an epoxy floor that stays clear for years.

Let’s dive deep into why some epoxy floors yellow and how you can prevent it.

Why Does Epoxy Turn Yellow?

Epoxy coatings contain polymers that react with UV light. When exposed to sunlight or strong indoor lighting, some epoxy types degrade, leading to yellowing and loss of clarity.

The main culprits behind yellowing include:

1. UV Exposure: The Primary Culprit

The biggest reason for yellowing in epoxy is UV exposure. Whether from direct sunlight or strong indoor lighting, UV rays trigger chemical reactions in the epoxy resin, leading to degradation and discoloration.

2. Chemical Composition of Epoxy

Not all epoxies are created equal. Some formulations contain ingredients that are more susceptible to UV damage. The difference between aromatic vs. aliphatic formulations plays a crucial role in UV stability.

3. Lack of UV-Resistant Topcoat

Even if you use high-quality epoxy, without a UV-resistant topcoat, your floor will be vulnerable to yellowing. Topcoat technology provides a protective shield that enhances UV stability in epoxy.

4. Oxidation and Environmental Factors

Other environmental factors, such as oxygen exposure, high humidity, and chemical interactions, can contribute to epoxy degradation.

Aromatic vs. Aliphatic Epoxy: The Key to UV Stability

Understanding aromatic vs. aliphatic formulations is essential when selecting an epoxy coating. These two types of epoxy have vastly different UV stability, longevity, and resistance to yellowing.

Aromatic Epoxy: Prone to Yellowing

Aromatic formulations are the most commonly used epoxies. They are affordable, strong, and easy to apply. However, they are not UV-resistant.

Why Aromatic Epoxy Yellows:

- Contains benzene rings that absorb UV light, leading to molecular breakdown.

- Oxidation accelerates yellowing, especially in high-humidity environments.

- Even indirect UV exposure can cause discoloration over time.

| Epoxy Type | UV Exposure Time | Color Change |

|---|---|---|

| Aromatic Epoxy | 3 months | Slight Yellowing |

| Aromatic Epoxy | 6 months | Moderate Yellowing |

| Aromatic Epoxy | 12 months | Severe Yellowing |

Even if aromatic epoxy looks clear when first applied, it will start yellowing within months if exposed to UV light.

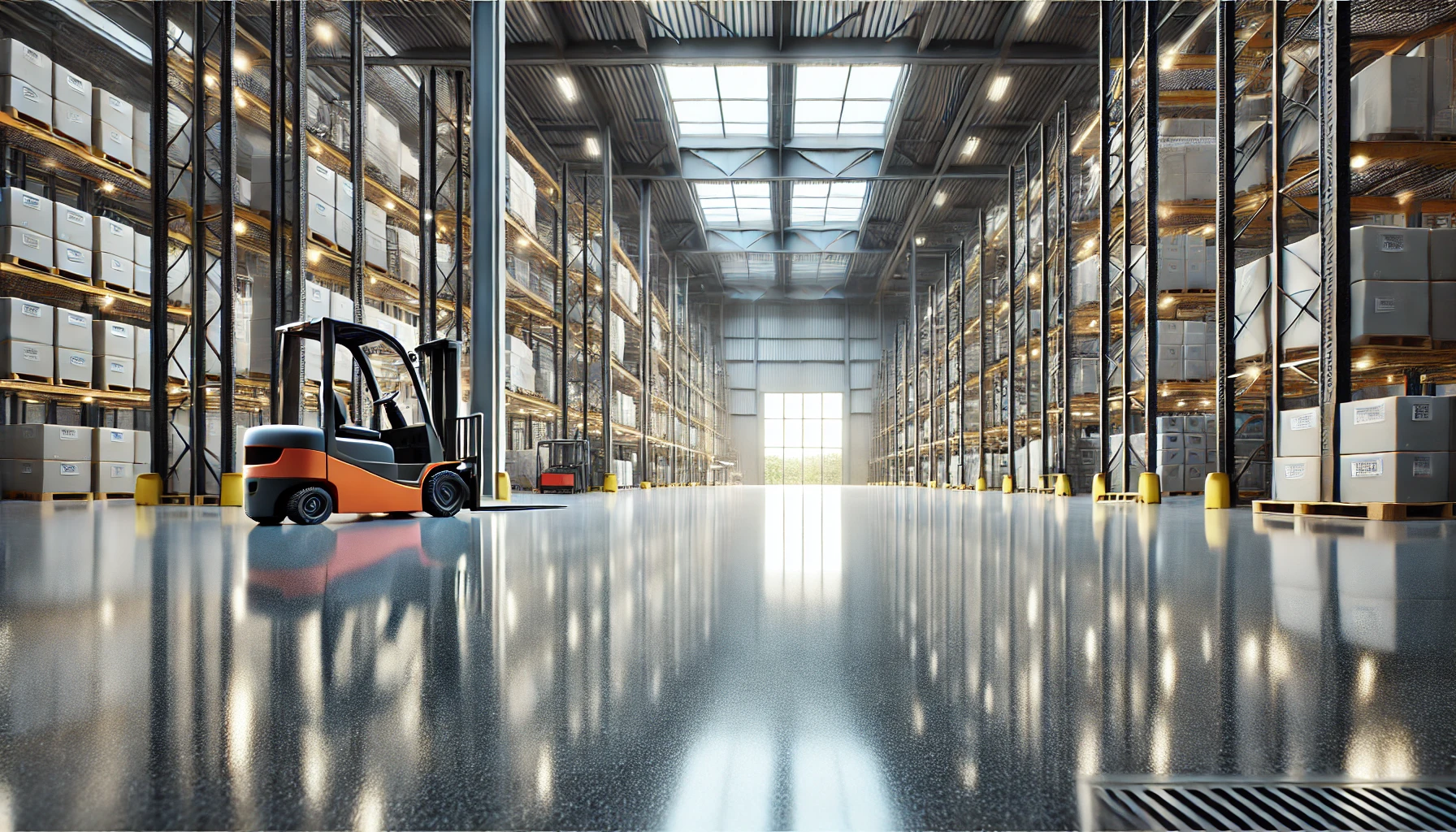

Aliphatic Epoxy: The UV-Resistant Solution

Aliphatic formulations are engineered for UV stability in epoxy. These epoxies are specifically designed to resist yellowing and maintain their clarity.

Why Aliphatic Epoxy Stays Clear:

- Does not contain benzene rings, making it highly UV-resistant.

- Excellent clarity, maintaining a crystal-clear finish for years.

- Resistant to oxidation, preventing color shifts over time.

- Ideal for both indoor and outdoor applications.

| Epoxy Type | UV Exposure Time | Color Change |

|---|---|---|

| Aliphatic Epoxy | 3 months | No Yellowing |

| Aliphatic Epoxy | 6 months | No Yellowing |

| Aliphatic Epoxy | 12 months | No Yellowing |

Aliphatic formulations are the best choice for long-term durability and clarity.

The Role of Topcoat Technology in Preventing Yellowing

Even the best aliphatic formulations benefit from a UV-resistant topcoat. Topcoat technology provides an extra layer of protection against UV damage, chemical exposure, and wear.

| Topcoat Type | UV Protection Level | Durability |

|---|---|---|

| Polyurethane | High | Excellent |

| Polyaspartic | Very High | Superior |

| Acrylic | Moderate | Good |

- Polyurethane topcoats: Provide good UV protection and are ideal for commercial spaces.

- Polyaspartic topcoats: Offer superior UV resistance, making them ideal for outdoor areas.

- Acrylic topcoats: Work for budget-friendly indoor projects but may not provide long-term UV stability in epoxy.

For the best protection, pair an aliphatic formulation with a polyaspartic or polyurethane topcoat.

Products We Use for UV Stability and Practical Applications

To ensure your epoxy floors stay crystal clear and resistant to yellowing, we use premium-grade materials specifically designed for UV protection and long-term durability.

Aliphatic Epoxy Products (Highly UV Resistant, Stay Clear for Years)

- Pure Epoxy Aliphatic Clear Coat – Ideal for garages, commercial spaces, and outdoor patios.

- Uniflex Aliphatic Epoxy – Best for industrial settings, outdoor applications, and high-traffic areas.

Polyaspartic Topcoats (Superior UV Resistance, Quick Curing)

- Pure Epoxy Polyaspartic Coating – Perfect for outdoor patios, driveways, and garage floors.

- Uniflex Polyaspartic 85 – Tailored for commercial and industrial floors exposed to sunlight.

Polyurethane Topcoats (High UV Resistance, Excellent Durability)

- Pure Epoxy Polyurethane Topcoat – Best used in commercial spaces, retail stores, and showrooms.

- Uniflex Polyurethane Gloss Finish – Ideal for offices, lobbies, and other indoor areas with strong UV exposure.

How to Prevent Epoxy Floors from Yellowing

1. Choose the Right Epoxy

Always select aliphatic formulations if your floor will be exposed to UV light.

2. Apply a UV-Resistant Topcoat

Invest in high-quality topcoat technology like polyaspartic or polyurethane for extra protection.

3. Limit Direct Sunlight Exposure

For indoor spaces, use UV-blocking windows or curtains to reduce UV impact.

4. Regular Maintenance and Cleaning

Keep your epoxy floor in top condition with gentle cleaning products that do not degrade the UV stability in epoxy.

5. Work with Professional Installers

Hiring experts ensures the right epoxy formulation and topcoat technology are used for maximum durability.

The Key to Long-Lasting Epoxy Floors

If you want an epoxy floor that stays crystal clear, focus on UV stability in epoxy.

- Avoid aromatic formulations if your floor will be exposed to sunlight.

- Choose aliphatic epoxy for maximum clarity and UV resistance.

- Use topcoat technology like polyaspartic or polyurethane for extra protection.

By following these steps, you can enjoy a beautiful, long-lasting epoxy floor without worrying about yellowing.

Frequently Asked Questions

How long does it take for epoxy to turn yellow?

Aromatic epoxy can start yellowing in as little as 3 months under UV exposure. Aliphatic epoxy, when properly coated, remains clear for years.

Can you fix the yellowed epoxy?

Once epoxy turns yellow, it cannot be reversed. However, you can apply a UV-resistant topcoat to prevent further discoloration.

Is there a 100% UV-resistant epoxy?

No epoxy is 100% UV-proof, but aliphatic epoxy with a polyaspartic or polyurethane topcoat offers maximum UV stability.

Does indoor epoxy flooring need UV protection?

Yes! Even indoor epoxy floors can be yellow from indirect sunlight or artificial lighting. Using a UV-resistant topcoat is recommended.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

We provide durable epoxy and polyaspartic flooring for garages, basements, warehouses, and commercial spaces. Serving Toronto, Vaughan, Mississauga, Markham, and beyond, we ensure fast, high-quality installations.

Epoxy Services

Contact us

Business Hours

- Mon - Sun

- -

Google Reviews

Edit Google Reviews Widget

Call

+1 647 955 6885@ 2025 All Rights Reserved || Crystal Clear Epoxy Inc