Epoxy Flooring vs. Polished Concrete: Which Is Right

Discover the key differences between epoxy flooring and polished concrete to determine which flooring option is best suited for your environment's needs.

Durability and Longevity

Epoxy flooring is renowned for its resistance to heavy loads and chemicals, making it ideal for industrial settings. In contrast, polished concrete offers exceptional durability and low maintenance, perfect for high-traffic areas in both commercial and residential settings.

Maintenance Needs

While epoxy flooring requires resealing and careful maintenance to retain its aesthetic, polished concrete needs only routine cleaning, significantly reducing upkeep costs.

Cost Considerations

Initial installation costs for epoxy can be higher, but polished concrete often emerges as a more budget-friendly option over time due to minimal maintenance requirements.

When it comes to selecting the ideal flooring solution for your space, the decision often boils down to balancing aesthetics, functionality, and long-term durability. In the realm of robust flooring options, two contenders stand out: epoxy flooring and polished concrete. Each offers unique benefits and suits different environmental demands, making the choice not just a matter of preference but of strategic decision-making. This guide dives into the core of epoxy and polished concrete floors, unpacking their strengths, weaknesses, and best use cases to help you make an informed choice that aligns with your specific needs. Whether you’re outfitting a high-traffic industrial area or enhancing a chic commercial setting, understanding the nuances of these flooring types is crucial in crafting a space that is as practical as it is appealing.

Epoxy is a thick coating that is glossy and damage-resistant, and therefore, it is used in industry settings. On the other hand, polished concrete offers a more sophisticated to a building yet is very durable. Their differences in maintenance, cost, and IFT learners to which industry will help us determine which flooring seems most appropriate.

Polished Concrete vs. Epoxy Resins: Debating which is the best, which is the most ideal finish for your working space? To avoid the questions step by step, we should first discuss the actual “working space” where the discussion will be most likely driven.

Durability and Longevity Comparison

Concerning durability, epoxy flooring and polished concrete are great options, though some striking differences exist. The use of epoxy flooring is favoured due to its high resistance to abrasion, chemicals, and loads of heavy equipment, making it even more suitable for use in factories and warehouses.

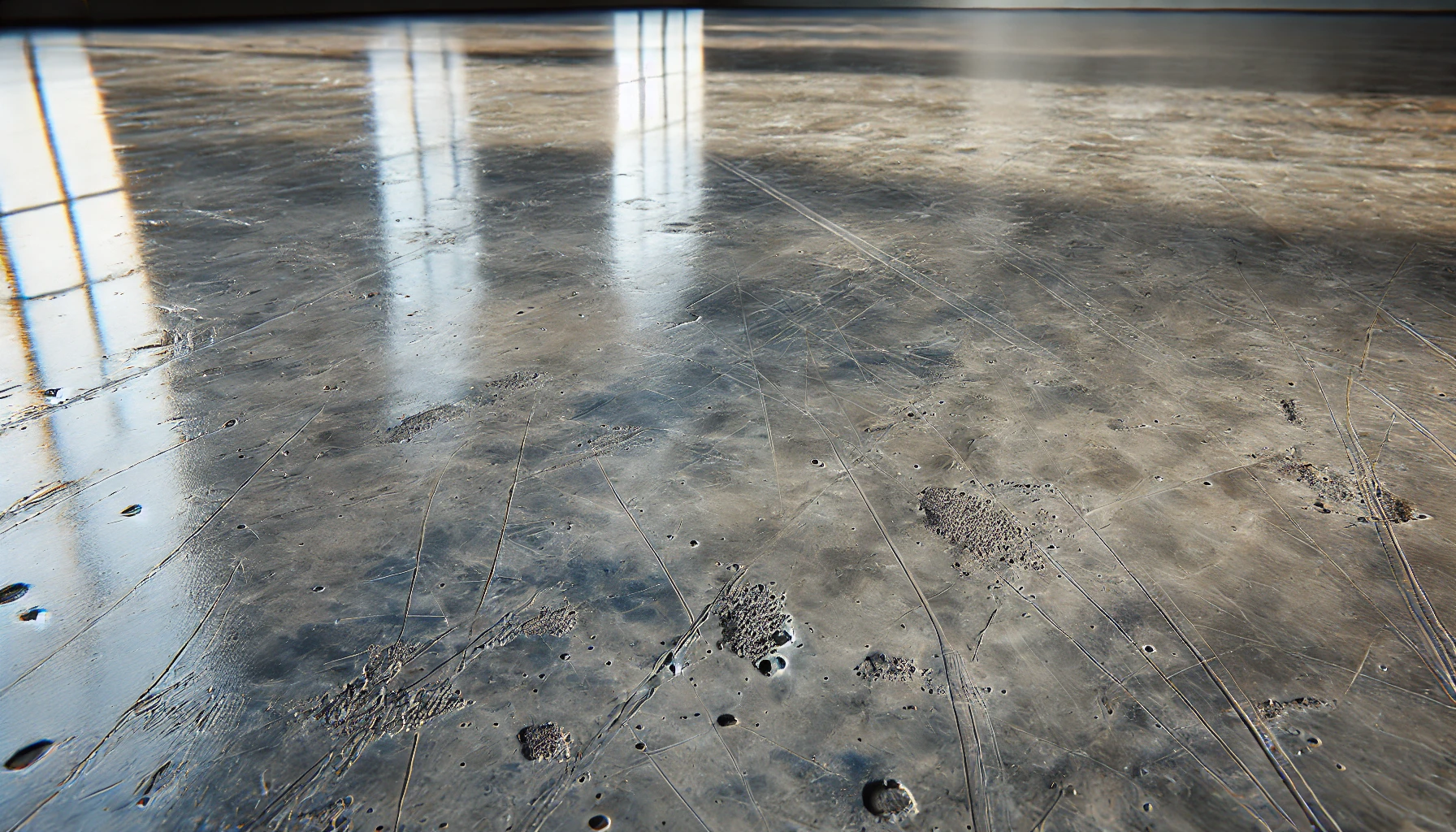

It creates a firm surface capable of enduring heavy impacts and traffic. However, for its long-term effectiveness, epoxy will require close maintenance as it is prone to peeling and chipping off over time. Conversely, polished concrete has superb strength and is guaranteed to last more than 30 years without regular maintenance. Such material is resistant to scratches and abrasions and can't peel or chip, making it an excellent surface material.

Its long-lasting effect is mainly a result of the raw durability of the concrete, which makes it even more effective for use in high-traffic zones in both commercial shops and residential apartments. Even though both are durable, polished concrete is more flexible regarding pore size as its staining and abrasion resistance is higher than epoxy flooring, making it longer-lasting and more efficient in many situations.

Epoxy vs. Concrete: Maintenance Needs

Epoxy Flooring Maintenance:

- It requires cleaning to maintain its glossy finish.

- It needs resealing or re-coating every few years, especially in high-traffic areas.

- The potential for peeling or chipping means monitoring and touch-ups may be necessary.

- Sensitive to certain chemicals that can affect its surface over time.

Polished Concrete Maintenance:

- Minimal maintenance is needed due to its natural strength.

- Routine sweeping and occasional mopping with neutral cleaners is usually sufficient.

- There is no need for waxing, sealants, or coatings, reducing long-term maintenance costs.

- Resistant to moisture and chemicals, reducing upkeep requirements.

Cost Differences and Budget Considerations

The costs of installing and maintaining epoxy floors and polished concrete differ greatly in their approaches. Due to the materials procurement and need for professionals, epoxy flooring has a greater cost at the beginning. The amount to be paid ranges based on the area covered and the number of epoxy layers installed.

While it might be expensive initially, one should understand that re-coating will be required every few years, so this would raise the overall expenses in the long run, particularly if care is not taken. On the other hand, polished concrete has always been the less expensive alternative. The initial cost is less since the existing concrete is ground down, which, in most cases, is already owned property.

Moreover, its economic efficiency is enhanced even more by the absence of constant upkeep. Both methods have their costs; however, given that the budget for the project is limited, polished concrete would be a more cost-effective option because of its low installation and maintenance costs. These elements must be considered when working on a specific flooring project to ensure that the flooring you choose is cost-effective in terms of your requirements.

Industry Suitability for Epoxy Flooring

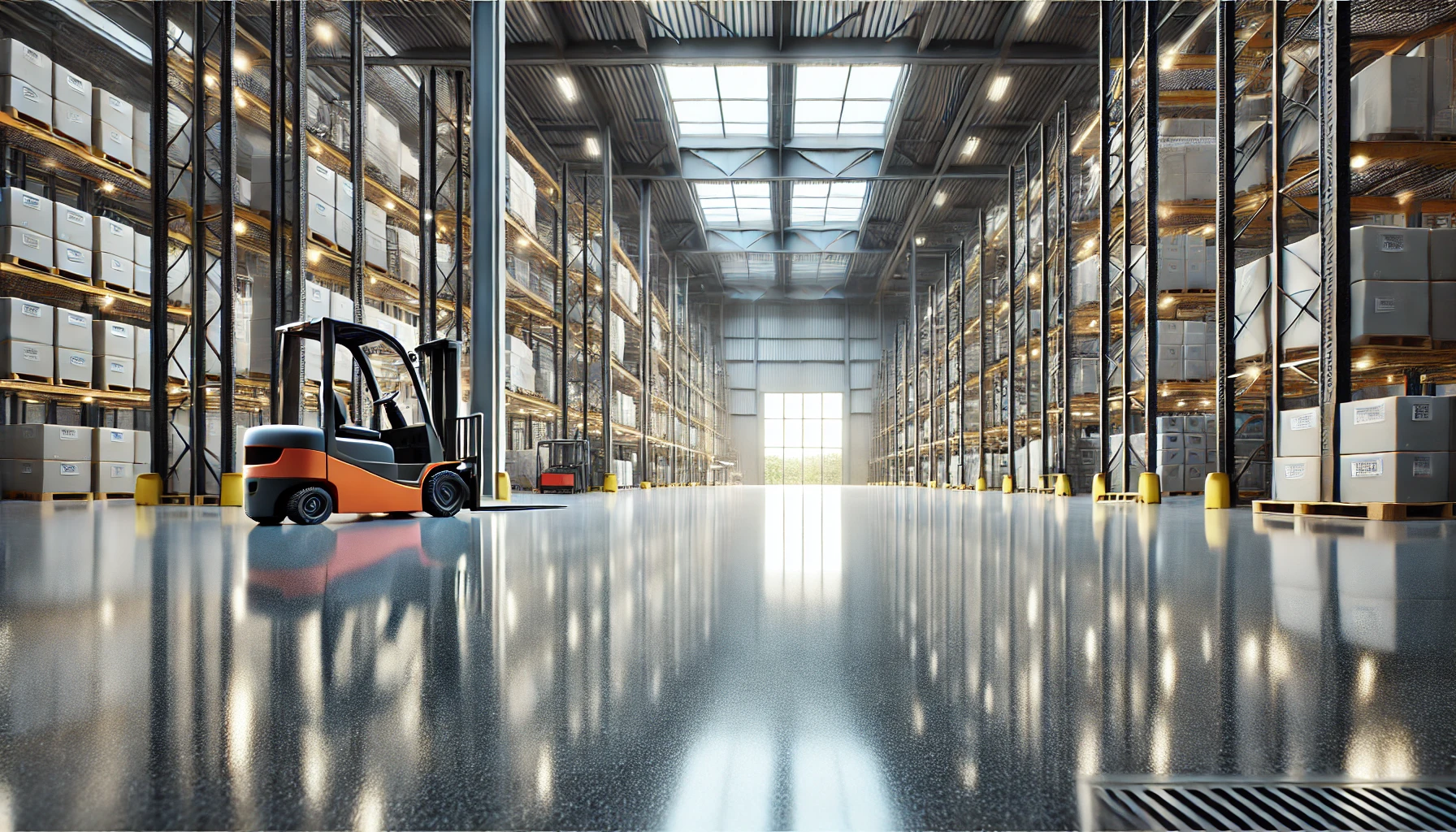

Epoxy flooring is a great solution for industries where tough and durable floor systems are needed. Such conditions demand considerable foot traffic or machinery like in warehouses or manufacturing plants which can use epoxy flooring as it offers great resistance against heavy loads, chemicals, and abrasion.

Moreover, epoxy systems are non-porous and easy to clean which is necessary for industries that have high requirements for cleanliness like food and pharmaceutical industries. However, epoxy coatings are also found in commercial buildings such as shops and car showrooms since the glossy and sleek surface enhances the beauty of the place.

This may decrease its attractiveness to places with a more natural look or without heavy-duty requirements. However, given specific factors in a given industry, there are existing solutions with regards to cost which can be used in heavy duty environments which also look good.

Polished Concrete in Commercial Settings

Polished Concrete Floors enhance the aesthetic appeal of a workplace. These floors are a more sought-after option with stores, hotels, and offices due to their ability to brighten the interiors through natural and artificial light. This shines through as polished concrete has a modern look while also being able to blend in minimalistic and industrial designs. Polished concrete is visually pleasing and durable, as it can withstand significant foot traffic without being repaired constantly.

Routine cleaning, such as simple dusting or mopping, suffices to maintain shine on the floors, which is a lower maintenance cost than other flooring options. With their ever-growing demand and benefits, polished concrete floors are cost-effective and eco-friendly as they barely require other coatings and materials.

With their ability to withstand time while boasting a stylistic aesthetic, polished concrete floors are the best option for commercial environments seeking an upgrade.

How do I choose between epoxy flooring and polished concrete for my space?

Assess your site's requirements. Consider traffic levels, exposure to chemicals, and the amount of money available to spend. Epoxy is best for surfaces that require chemical resistance and can take the hardest blows. When looking for a natural, low-maintenance finish, polished concrete will work well. With that, consider the maintenance aspect of the flooring you choose in the long term.

What is the expected lifespan of epoxy flooring and polished concrete?

The durability of epoxy floors can last between five to ten years based on the level of traffic and how much maintenance is provided. Areas with high tread will have a higher frequency of the re-coating process. Given its resistance to scratches and low maintenance, polished concrete can last a few decades with regular maintenance. Maximizing the lifespan of both can quickly be done by following the provided maintenance and care procedures.

Are epoxy floors eco-friendly?

Basing the argument on sustainability, polished concrete looks blue as it uses existing structures and low materials. Epoxy floors trigger environmental concerns due to the use of synthetic resins and other chemicals during the application process. For the concerns raised, however, an argument can be made that does make sense, as their structural importance can potentially minimize the need for replacement materials.

Can the finishing of polished concrete be tailored for aesthetic improvement?

Polished concrete offers many customization options. You may select the finish you want, including matte or high gloss, and various color staining techniques. You can also incorporate aggregates or chemicals to create patterns or textures for a more unique and appealing design. This level of versatility is what makes a polished concrete layer fashionable while reminding its users not to sacrifice strength or compliment.

Frequently Asked Questions

When opting between these two solutions, think of the upfront cost, ongoing need for care, and requirements of that particular industry. Epoxy flooring is fitted for environments with stringent sanitary conditions and where loss of time would be an issue, such as industrial sites and commercial areas where chemicals are used. In contrast, a polished concrete floor is a more affordable option for commercial spaces, such as shops and offices, with a lowered level of care and a pleasing look. I suggest exploring your requirements along with the relevant budget so that you can easily complement your operational needs and aesthetic sense.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

We provide durable epoxy and polyaspartic flooring for garages, basements, warehouses, and commercial spaces. Serving Toronto, Vaughan, Mississauga, Markham, and beyond, we ensure fast, high-quality installations.

Epoxy Services

Contact us

Business Hours

- Mon - Sun

- -

Google Reviews

Edit Google Reviews Widget

Call

+1 647 955 6885@ 2025 All Rights Reserved || Crystal Clear Epoxy Inc