What to Do if Your Epoxy Floor Starts Peeling: A Comprehensive Guide to Repair and Prevention

What to Do If Your Epoxy Floor Starts Peeling

Epoxy floor peeling occurs when the bond between the coating and the concrete weakens. Here's how to repair and prevent it:

- Identify the Cause: Common causes include poor surface preparation, trapped moisture, and improper curing.

- Spot Repairs: Sand the affected area, clean thoroughly, apply primer, and recoat with epoxy.

- Full Re-Coating: For severe damage, remove the old epoxy, prepare the surface, prime, and apply a new epoxy layer.

- Prevention Tips: Ensure proper surface prep, control moisture, use high-quality epoxy, and avoid harsh cleaners.

Restore your epoxy floors and keep them in top condition!

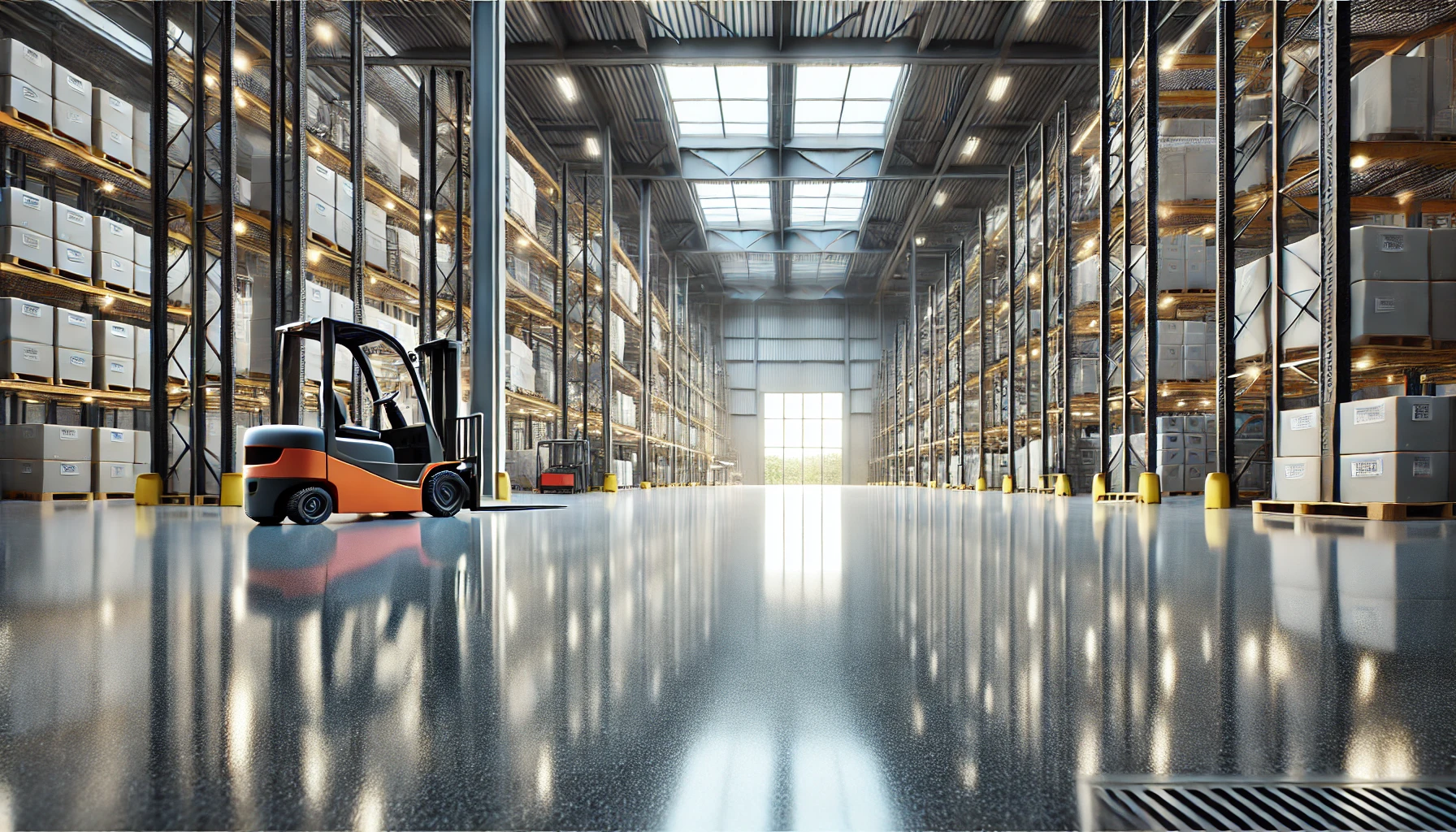

Epoxy floors are an excellent investment for various spaces, offering durability, aesthetics, and protection for concrete surfaces. Whether it’s a high-traffic warehouse, a stylish garage floor, or a commercial space, epoxy coatings are designed to withstand heavy use and provide long-lasting results.

However, like any flooring solution, epoxy floors can face issues over time. One of the most frustrating problems you might encounter is peeling.

In this detailed guide, we’ll walk you through the causes of epoxy floor peeling, how to perform epoxy floor peeling repair, and the steps you can take to prevent this problem from occurring in the first place.

Why Do Epoxy Floors Peel? Understanding the Causes

Before you can fix a peeling epoxy floor, you need to understand what causes it. Peeling occurs when the bond between the epoxy coating and the concrete substrate weakens. Several factors contribute to this issue, and understanding these causes is crucial in determining the best course of action.

Improper Surface Preparation

One of the most common causes of epoxy floor peeling is improper surface preparation before application. If the concrete is not thoroughly cleaned, ground, or primed, the epoxy will struggle to adhere properly, leading to peeling over time. This can include:

- Dust and Debris: If the floor is not cleaned of dust, oil, grease, or other contaminants, the epoxy will have a hard time sticking to the concrete.

- Moisture Issues: Concrete that retains moisture or has high humidity can result in weak adhesion, causing peeling over time.

Incorrect Product Selection

Not all epoxy products are the same. Some are designed for residential applications, while others are formulated for industrial use. Using the wrong product for your specific needs—whether it's the wrong type of epoxy, wrong thickness, or incorrect curing time—can lead to premature failure and peeling.

Lack of Primer

A primer is essential for ensuring a strong bond between the epoxy and the substrate. If no primer is applied before the epoxy coat, the adhesion strength will be compromised, leading to peeling over time.

Moisture Content in Concrete

Moisture content in the concrete is a major factor that can lead to epoxy floor peeling. If there’s excess moisture in the concrete slab or if the area is prone to high humidity, the epoxy coating may fail to adhere. The moisture will cause the epoxy to lift and peel away from the floor.

Improper Application of Epoxy

Epoxy floors need to be applied in the correct thickness for optimal adhesion and durability. Applying too thin a layer of epoxy can result in a weakened coating that is more susceptible to peeling under stress or traffic. Conversely, applying too thick a coat can cause the epoxy to crack, leading to peeling.

Heavy Traffic and Wear

In environments with high traffic, forklifts, or heavy machinery, epoxy floors can take a beating. Over time, constant abrasion and impact from vehicles, equipment, and foot traffic can weaken the epoxy coating, causing it to peel.

Temperature and Curing Issues

Epoxy needs to be applied at the right temperature and allowed enough time to cure properly. If the environment is too cold or too hot, or if the curing process is rushed, the epoxy may fail to bond properly and peel prematurely depending on the specific product.

Cause of Failure

Understanding these causes helps determine whether you’re dealing with a localized issue or a systemic problem that requires complete floor replacement.

How to Identify If Your Epoxy Floor is Peeling

Peeling epoxy floors are easy to spot, but it’s important to differentiate between peeling and other types of damage, such as blistering or cracking. Here are the key signs of peeling:

- Visible Lifting: The most obvious sign of peeling is when sections of the epoxy coating begin to lift away from the surface.

- Discoloration: If the floor shows signs of discoloration or faded areas, it could indicate that the epoxy is losing its bond with the substrate.

- Bubbling or Cracking: If you notice bubbles or cracks forming in the epoxy, it’s a sign that the coating is no longer firmly adhered to the concrete.

- Dust and Debris: As the floor starts to peel, dust and debris will often collect in the peeling areas, contributing to a dirty, unattractive appearance.

Common Epoxy Problems Beyond Peeling

Peeling is just one of the many challenges epoxy floors might face. Here's a table highlighting common epoxy problems, their causes, and solutions:

Problem, Cause, and Solution

| Problem | Cause | Solution |

|---|---|---|

| Peeling | Poor surface prep, moisture issues | Sand, clean, and reapply epoxy |

| Bubbles/Blisters | Trapped air or improper curing | Sand and recoat |

| Cracks | Substrate movement or impact damage | Fill cracks with epoxy filler |

| Dull Finish | Harsh chemicals or improper cleaners | Polish or apply a new topcoat |

| Yellowing | UV exposure or low-quality epoxy | Use UV-resistant epoxy for recoating |

How to Fix Peeling Epoxy Floors

If you’re dealing with epoxy floor peeling repairs, it’s important to take the right steps to fix the problem. Depending on the extent of the damage, the solution could range from a simple spot repair to a complete floor re-coating. Let’s explore both options.

Spot Repair for Localized Peeling

If only a small area of your floor is peeling, a localized repair can help restore the surface without the need for a complete re-coat.

Steps for Localized Peeling Repair:

- Clean the Area: Start by cleaning the affected area thoroughly. Use a degreaser or solvent to remove any dirt, oil, or grease. Allow the area to dry completely.

- Sand the Peeling Area: Use a sander or sanding block to rough up the surface of the peeling area. This helps to remove any loose epoxy and creates a better surface for the new coating to adhere to.

- Prime the Surface: Apply a layer of epoxy primer to the cleaned and sanded area. The primer will help the new epoxy bond properly with the concrete.

- Reapply Epoxy: Once the primer is dry, mix and apply the new epoxy coating to the affected area. Allow it to cure according to the manufacturer’s instructions.

Pro Tip: Always ensure that the area you’re repairing is thoroughly dry before reapplying epoxy to prevent any further peeling.

Full Re-Coating for Extensive Peeling

If the peeling is widespread or if the damage is severe, a full re-coat may be necessary. While this can be more time-consuming and costly, it is often the best solution to restore the entire floor.

Steps for Full Re-Coating:

- Remove the Existing Epoxy Coating: Start by removing the damaged epoxy layer. This can be done using a chemical stripper or a floor grinder. Be sure to remove all of the old epoxy to ensure the new coat bonds properly.

- Clean and Prepare the Concrete Surface: After stripping the old coating, clean the concrete thoroughly. You may need to use a power washer or scrub the surface with a cleaning solution to remove any remaining dust or debris.

- Repair Any Concrete Damage: If there are cracks, chips, or holes in the concrete, repair them with a concrete patching compound or by injecting epoxy. Allow the patch or epoxy to cure before moving on.

- Prime the Floor: Apply a high-quality epoxy primer to the entire surface. This helps the new epoxy coat bond effectively.

- Apply New Epoxy Coating: Finally, mix and apply the new epoxy coating according to the manufacturer’s instructions. For added durability, it’s often recommended to apply two coats of epoxy or one thicker layer.

Cost of Epoxy Floor Peeling Repair

| Type of Repair | Estimated Cost |

|---|---|

| Spot Repair | $3–$5 per sq. ft. |

| Complete Removal & Reapplication | $10–$15 per sq. ft. |

| DIY Tools & Materials | $200–$500 (one-time cost) |

| Professional Services | $1,500–$4,000 (average) |

Investing in professional services is often worth the cost, especially for widespread peeling. DIY repairs are cost-effective but require skill and attention to detail.

Tips for Longevity

The best way to avoid the hassle of epoxy floor peeling repair is to prevent the problem from occurring in the first place. Here are some tips to ensure your epoxy floors last longer and remain in top condition:

- Proper Surface Preparation: Always ensure that the concrete surface is clean, dry, and properly prepared before applying epoxy. This includes cleaning the floor thoroughly, repairing cracks, and using a primer if necessary.

- Choose the Right Product: Make sure to select the right type of epoxy for your specific needs. For high-traffic areas, industrial-grade epoxy is recommended for added durability.

- Control Moisture: High moisture levels in concrete can cause epoxy to peel. Ensure that the concrete has low moisture content and address any issues with a vapor barrier before applying epoxy.

- Avoid Harsh Chemicals: Use mild cleaning products for regular maintenance. Harsh chemicals can break down the epoxy, leading to peeling and other damage.

- Regular Inspections and Maintenance: Conduct regular inspections to spot any early signs of wear, and repair small issues before they become bigger problems.

Protect Your Investment with Professional Epoxy Flooring Services

If your epoxy floor is peeling, it’s important to act quickly to prevent further damage. Whether you need spot repair or a full re-coating, addressing the issue early can save you time and money in the long run.

For expert epoxy flooring peeling repair service, count on us atCrystal Clear Epoxy flooring. Our experienced team can restore your epoxy floors to their original condition and help you avoid common epoxy problems in the future.

Contact us today for a free consultation or to schedule an appointment. We’re here to ensure your floors stay beautiful and functional for years to come!

Frequently Asked Questions

How do I know if my epoxy floor needs repairs or a full replacement?

If the peeling is localized, spot repairs may be enough. However, widespread peeling, multiple cracks, or significant wear indicate that a full removal and reapplication are the best solutions.

How long does epoxy floor repair take?

Spot repairs can take 1–2 days, including drying time. A full re-coating typically takes 3–5 days, depending on the preparation work, curing time, and the size of the space.

Can I apply epoxy over an old epoxy floor?

Yes, you can recoat over old epoxy, but the existing surface must be sanded to remove loose or peeling areas, cleaned thoroughly, and primed to ensure proper adhesion.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

We provide durable epoxy and polyaspartic flooring for garages, basements, warehouses, and commercial spaces. Serving Toronto, Vaughan, Mississauga, Markham, and beyond, we ensure fast, high-quality installations.

Epoxy Services

Contact us

Business Hours

- Mon - Sun

- -

Google Reviews

Edit Google Reviews Widget

Call

+1 647 955 6885@ 2025 All Rights Reserved || Crystal Clear Epoxy Inc