Polyurea vs. Epoxy: Garage Floor Coatings | Crystal Clear Epoxy

Explore the detailed comparison between Polyurea and Epoxy floor coatings. Understand their properties to determine which is the best choice for your garage.

- What is Polyurea?

- Chemical Properties of Polyurea

- What is Epoxy?

- Installation Process

- Durability

- Longevity

- Pricing

- Maintenance

- FAQs

Choosing the right garage floor coating is crucial for ensuring durability, aesthetics, and long-term maintenance. This guide will provide an in-depth comparison between polyurea and epoxy coatings, helping you make an informed decision. Whether you are a homeowner aiming to enhance your garage or a professional contractor seeking the best solutions, understanding these options will guide you to the right choice.

What is Polyurea?

Polyurea is a type of elastomer that forms through step-growth polymerization where a chemical process where small molecules, known as monomers, join together to form a larger molecule called a polymer. In step-growth polymerization, the process happens in stages, with monomers reacting in pairs to form dimers (two-unit molecules), which then react to form trimers (three-unit molecules), and so on. This continues until long polymer chains are created.

The reaction involves an isocyanate component and a resin blend component. Isocyanates are a group of highly reactive chemicals that contain a specific functional group known as the isocyanate group (-N=C=O). These chemicals are crucial in creating polyurethane and polyurea materials. When isocyanates react with compounds that have hydroxyl groups (-OH), such as the resin blend component, they form strong urethane or urea linkages, resulting in durable and flexible polymers. The resin blend in polyurea coatings typically contains a mix of polyamines, which are compounds with multiple amine groups (-NH2). These amines react with the isocyanates to form polyurea. The specific formulation of the resin blend can be adjusted to enhance certain properties of the final product, such as flexibility, hardness, or chemical resistance. This give polyurea its rapid curing time and exceptional flexibility, polyurea offers numerous benefits that make it a preferred choice for garage floors and other applications.

Chemical Properties of Polyurea

Polyurea’s unique chemical structure endows it with superior properties, making it highly suitable for demanding environments.

Moisture Resistance

Polyurea is inherently hydrophobic, meaning it repels water. This property is crucial for preventing water infiltration and damage, which is especially beneficial in areas prone to moisture, such as garages, basements, and outdoor spaces. The moisture resistance of polyurea coatings ensures that the underlying concrete remains protected from water-induced degradation, such as cracking, spalling, and mold growth.

Chemical Resistance

Polyurea’s chemical structure includes strong urethane linkages, which provide excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and oils. This makes polyurea coatings ideal for industrial settings where chemical spills are common. The chemical resistance ensures that the coating will not degrade or lose its integrity when exposed to harsh substances, maintaining a safe and clean environment.

Abrasion Resistance

The flexibility and toughness of polyurea result in exceptional abrasion resistance. This means that polyurea-coated surfaces can withstand heavy wear and tear from foot traffic, vehicles, and machinery without showing signs of damage. The ability to resist abrasions extends the life of the coating, making it a cost-effective solution for high-traffic areas.

Flexibility and Impact Resistance

Polyurea is highly flexible, allowing it to absorb impacts and adapt to substrate movements without cracking or peeling. This flexibility is particularly important in regions with significant temperature fluctuations, where materials expand and contract.

Rapid Curing and Odorless Application

The rapid curing time of polyurea is a result of its chemical reaction kinetics. When the isocyanate component reacts with the resin blend component, the reaction proceeds very quickly, forming a polymer network almost immediately. This fast reaction is facilitated by the high reactivity of the isocyanate and amine groups in the resin blend. As a result, polyurea coatings can set and cure within minutes to a few hours, significantly faster than epoxy coatings, which may take several days to fully cure. This quick curing time reduces downtime and allows for faster project completion, making polyurea a highly efficient solution for flooring applications. Additionally, polyurea is virtually odorless during application, which improves indoor air quality and makes the installation process more pleasant for both workers and occupants.

Common Applications

Beyond garage floors, polyurea is used in various industrial and commercial settings, including:

- Industrial flooring

- Tank liners

- Secondary containment areas

- Roof coatings

What is Epoxy?

Epoxy is a thermosetting polymer formed from the reaction between an epoxide resin and a polyamine hardener. When the epoxy resin and polyamine hardener are mixed, a chemical reaction called curing or polymerization occurs. This reaction transforms the liquid components into a solid, thermoset polymer. The curing process involves the formation of strong covalent bonds between the resin and hardener molecules, creating a dense, tightly-knit molecular structure. It is well-regarded for its strong adhesive properties, chemical resistance, and durability, making it a popular choice for various flooring applications.

Chemical Properties of epoxy

Epoxy's adhesive strength is one of its most notable characteristics.

Strong Adhesive Properties

Epoxy's adhesive strength is one of its most notable characteristics. It forms a strong bond with various substrates, including concrete, metal, and wood. This makes it an excellent choice for flooring applications, where a durable bond to the concrete surface is essential. The adhesive properties of epoxy also help to seal and protect the underlying material from moisture and chemical infiltration.

Chemical Resistance

Epoxy coatings offer exceptional chemical resistance, making them ideal for environments exposed to corrosive substances. The cross-linked polymer structure provides a barrier that similarly to polyurea resists penetration by chemicals such as acids, alkalis, solvents, and oils. This resistance ensures that epoxy-coated surfaces remain intact and unaffected by spills and splashes, maintaining a safe and clean environment.

Durability

Epoxy is renowned for its durability and ability to withstand heavy traffic and mechanical loads. Its hard, rigid surface is resistant to wear and tear, abrasions, and impacts.

Common Applications

Epoxy coatings are widely used in various settings due to their versatile properties:

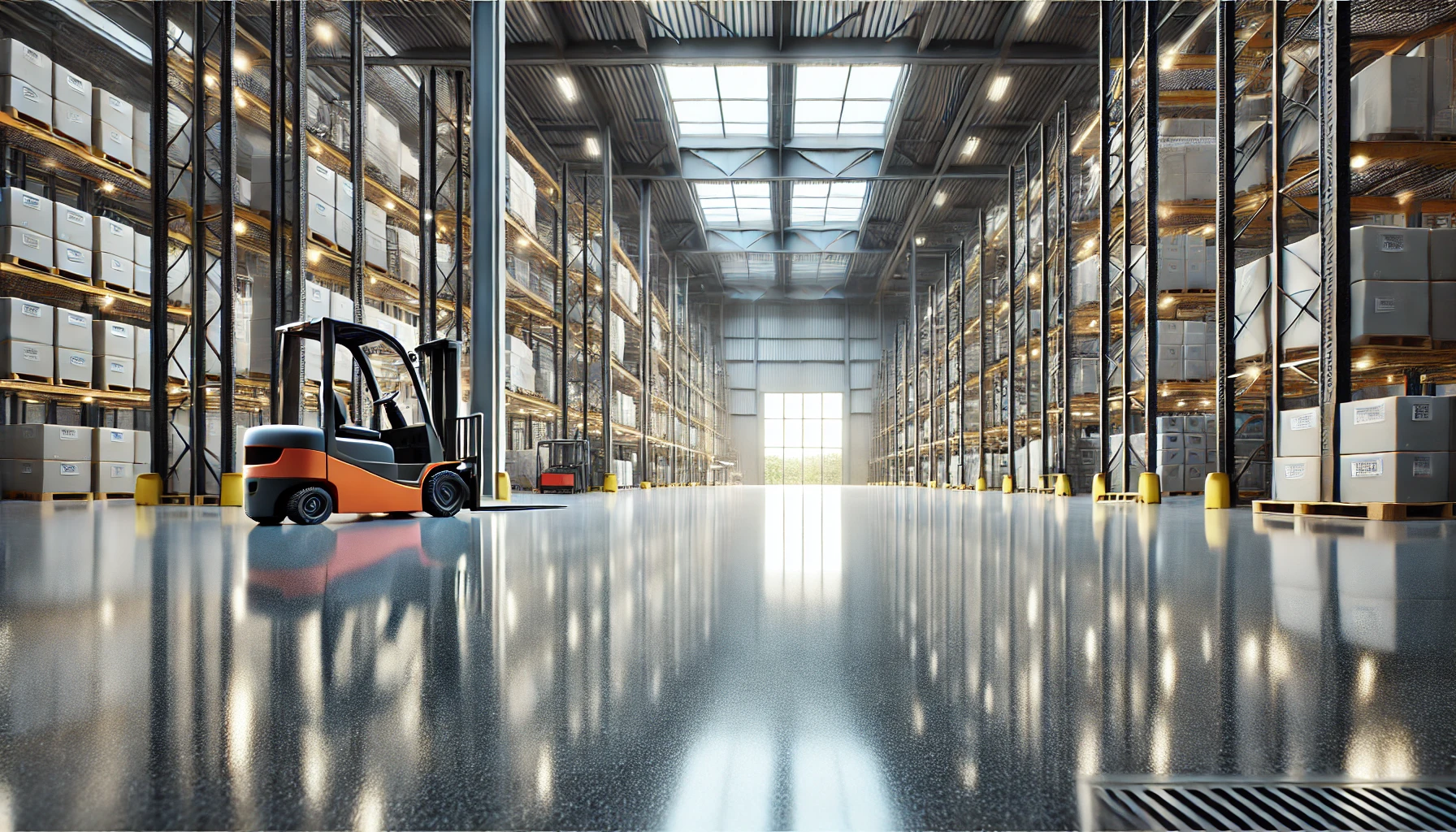

- Residential Garages: Provides a durable, easy-to-clean surface that resists oil stains and tire marks.

- Commercial and Industrial Floors: Ideal for warehouses, factories, and laboratories where durability and chemical resistance are critical.

- Decorative Flooring: Epoxy can be mixed with colorants and decorative chips to create aesthetically pleasing floors in retail stores, showrooms, and homes.

- Protective Coatings: Used on metal surfaces and concrete structures to protect against corrosion and environmental damage.

Customizability

One of the advantages of epoxy is its customizability. It can be formulated with various additives to enhance specific properties, such as increased flexibility, improved UV resistance, or faster curing times. Additionally, epoxy can be tinted with different colors and combined with decorative flakes or metallic pigments to create visually appealing finishes.

Epoxy's combination of strong adhesive properties, chemical resistance, and durability makes it a popular choice for a wide range of flooring applications. Its ability to provide a protective, easy-to-maintain surface while also being customizable for specific needs makes it a versatile and reliable option for both residential and commercial use.

Comparative Analysis: Polyurea vs. Epoxy

Now that we have a deeper understand of epoxy and polyurea, we can analyze them and compare them.

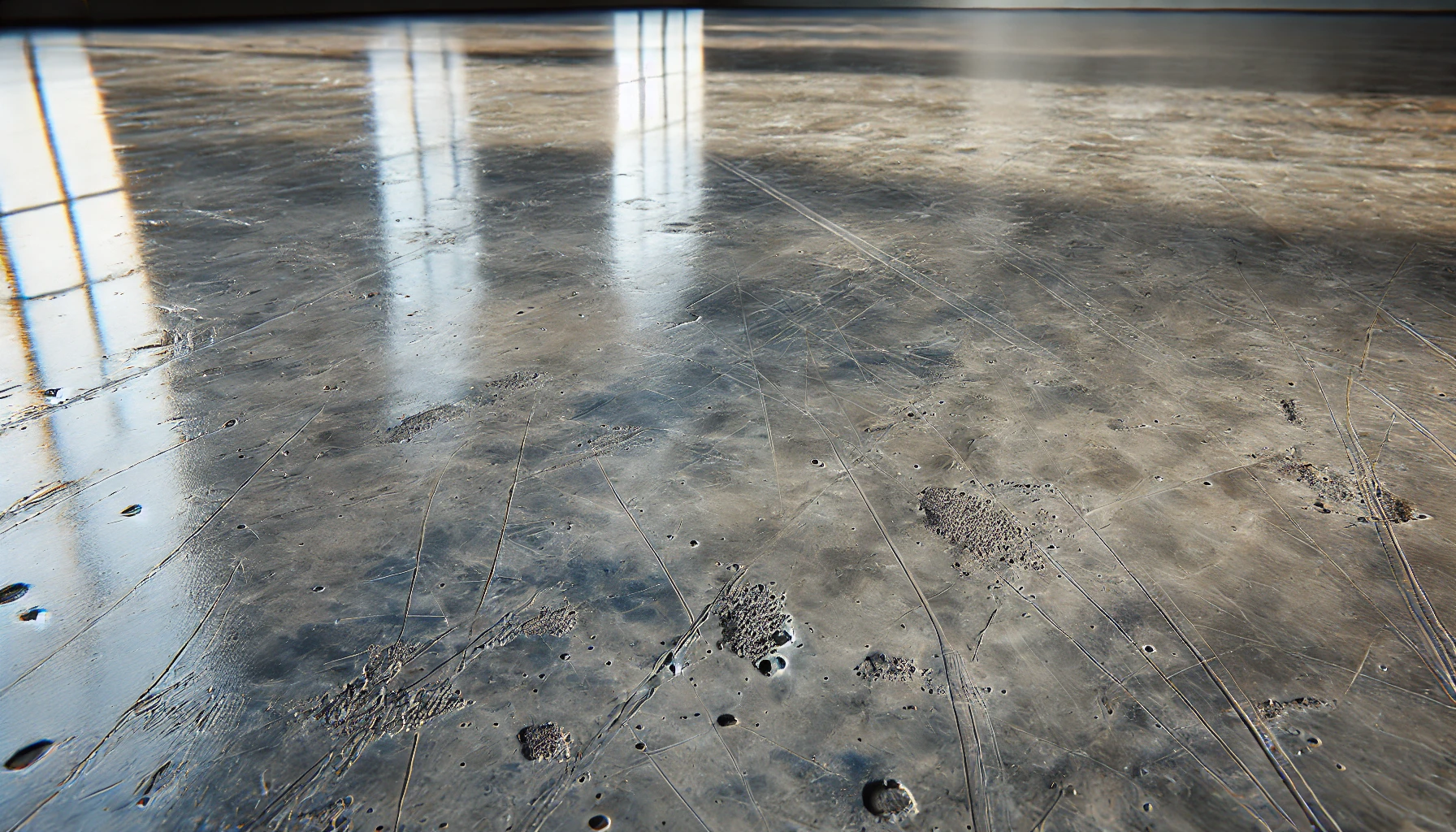

Durability

Polyurea and epoxy both offer durability, but polyurea stands out due to its flexibility and resistance to impacts and abrasions. Epoxy, while durable, is more susceptible to chipping and yellowing over time, especially under UV exposure.

Installation Process

Polyurea coatings have a rapid curing time, often drying within 24 hours whereas epoxy coatings require a longer curing period, typically taking several days to fully harden. The installation process involves surface preparation, primer application, and multiple layers of epoxy.

Environmental Resistance

Polyurea’s resistance to moisture and chemicals makes it ideal for environments with high humidity or exposure to spills. Epoxy is also resistant to chemicals but may not perform as well in consistently damp conditions.

Longevity

Polyurea coatings are renowned for their long lifespan, often lasting upwards of 15-20 years with proper maintenance. This longevity is due to their flexibility and resistance to environmental factors. Epoxy coatings, on the other hand, typically last around 5-10 years, depending on the level of wear and exposure to harsh conditions.

Pricing

The initial cost of polyurea is typically higher than epoxy, but its long-term benefits and reduced maintenance costs can offset this. Polyurea’s durability means fewer repairs and replacements over time, leading to long-term savings. Epoxy is more budget-friendly upfront but may require more frequent repairs and replacements, increasing the overall cost over time.

Decorative Flexibility

Epoxy offers greater flexibility in decorative finishes. It can be easily tinted with various colors and combined with decorative flakes or metallic pigments to create unique, aesthetically pleasing designs. This makes epoxy a popular choice for environments where appearance is a key consideration, such as showrooms, retail spaces, and residential garages.

UV Resistance Enhancement

While standard epoxy is prone to yellowing under UV exposure, there are UV-resistant epoxy formulations available. These specialized epoxies include UV stabilizers that enhance their resistance to sunlight, making them more suitable for outdoor applications or areas with significant sunlight exposure.

Considerations For Polyaspartic Floor Coatings

Polyaspartic coatings, a subtype of polyurea, can combine the best properties of polyurea and epoxy, offering a versatile and durable solution for garage floors. Here are some key benefits:

Faster and More Convenient Application

Polyaspartic coatings can be applied quickly and efficiently, often completing within a single day. This minimizes disruption and allows you to use your garage sooner.

Cures in Hot and Cold Temperatures

Polyaspartic coatings can cure in a wide range of temperatures, making them suitable for various climates and conditions. This flexibility ensures that the coating will perform well regardless of the environmental conditions.

Resistance to Hot Tire Pickup

Polyaspartic coatings are resistant to peeling caused by hot tires, ensuring a long-lasting, durable surface even under heavy use. This property is particularly important for garage floors, where vehicles frequently enter and exit.

High Gloss Polyaspartic Flooring

Write your caption hereButton

Decorative Flake Polyaspartic Flooring

Write your caption hereButton

Selecting the right floor coating is crucial for ensuring the long-term durability and visual appeal of your floors. Polyurea, polyaspartic, and epoxy coatings each bring unique advantages, catering to different needs and preferences. Polyurea stands out with its rapid curing and flexibility, polyaspartic offers enhanced UV resistance and versatility, while epoxy provides cost-effective and decorative solutions. Investing in a high-quality floor coating ensures a resilient, low-maintenance floor that will remain durable and attractive for years, making it a wise choice for both residential and commercial applications.

Frequently Asked Questions

Is a polyurea floor better than epoxy?

Polyurea is often considered better than epoxy due to its rapid curing time, flexibility, superior moisture and chemical resistance, and long-term durability. However, the best choice depends on specific needs and budget considerations.

What are the negatives of polyurea?

The main drawbacks of polyurea include its higher initial cost compared to epoxy and the need for professional installation due to its rapid curing time and application complexity.

Is polyurea worth the money?

Yes, polyurea is worth the investment for its long-term durability, minimal maintenance, and superior resistance to environmental factors. It can provide a high-quality, resilient floor that lasts for decades.

What is the best coating to put on a garage floor?

The best coating depends on your specific needs. Polyurea is excellent for durability and quick curing, while epoxy is cost-effective and offers decorative flexibility. Polyaspartic, a type of polyurea, is also highly recommended for its versatility and UV stability.

Does polyurea crack?

Polyurea is highly flexible and resistant to cracking, even in environments with significant temperature fluctuations or heavy mechanical impacts.

Is polyurea slippery when wet?

Polyurea can be slippery when wet, but anti-slip additives can be incorporated into the coating to enhance traction and safety.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

We provide durable epoxy and polyaspartic flooring for garages, basements, warehouses, and commercial spaces. Serving Toronto, Vaughan, Mississauga, Markham, and beyond, we ensure fast, high-quality installations.

Epoxy Services

Contact us

Business Hours

- Mon - Sun

- -

Google Reviews

Edit Google Reviews Widget

Call

+1 647 955 6885@ 2025 All Rights Reserved || Crystal Clear Epoxy Inc