Fiberglass, Acrylic, and Epoxy Resins Guide | Crystal Clear Epoxy

Introduction to Resins

The world of resins is vast and complex, with various types serving different purposes. Let's break down the three main kinds of resins used with fiberglass: polyester, acrylic, and epoxy.

Polyester Resin (Fiberglass Resin)

Polyester resin, commonly referred to as fiberglass resin, is the original resin used in the composite material known as fiberglass. It's composed of a mix of monomers, often 50/50 polyester/styrene in cheaper variants, and while it's durable and semi-flexible, it's not 100% waterproof. When it comes to adhesion, it's weaker as a glue compared to epoxy especially in commercial, industrial, and retail epoxy flooring applications. Polyester resin is commonly used in boats, windmill blades, vintage cars, and surfboards.

Epoxy Resin

Epoxy resin is renowned for its high strength and waterproofing capabilities. Composed of pure epoxy or mixed with expensive additives, it maintains superior properties. Its strength is such that it's used primarily as a very high-strength glue, and it also acts as a waterproof coating. Common applications include saturating and bonding fiberglass cloth to wood, as well as custom surfboard making, making it a preferred choice for many commercial, industrial, and retail flooring solutions.

Acrylic Resin

Though not as commonly discussed, acrylic resin plays a significant role in the industry. An acrylic resin is a thermoplastic or thermosetting plastic substance typically derived from acrylic acid, methacrylic acid, and acrylate monomers. It's often used in different liquid carriers such as hydrocarbon solvent or water, and it's also provided in 100% solids bead form. One notable example is polyhydroxyethylmethacrylate (pHEMA), which makes a crosslinked polymer when treated with polyisocyanates. Acrylic resin is a common ingredient in latex paint, offering better stain protection, greater water resistance, and resistance to alkali cleaners compared to vinyl-based resins. It's considered extremely weatherproof and well-suited for outdoor applications, as it does not yellow when exposed to sunlight. In solid form, acrylic resin can last for decades, and it's a useful component in some paints. Details about acrylic resin may be less prominent, but it's another versatile option in the resin family, with applications ranging from paint to construction materials.

Customization and Evolution

The industry has evolved, leading to the development of different properties by changing the type of monomer in the resin. Additives like vinyl ester enhance flexibility, while epoxy resin strengthens the composite. Professionals often mix their custom resin blend, tailoring it to their specific products.

Curing Process

The curing process is a pivotal phase in the development of various materials, playing a unique role in polymer chemistry and process engineering. For Polyester Resins, curing is typically triggered by adding a catalyst, applying heat, or exposing to ultraviolet light. Epoxy Resins, on the other hand, begin as two separate components that are mixed together, with the reaction initiated through heat, ultraviolet light, or even radio waves. This process of curing is a complex chemical transformation that results in the toughening or hardening of a polymer by creating cross-links between polymer chains. The method of curing can be influenced by factors such as heat, radiation, electron beams, or specific chemical additives, and it often varies depending on both the type of resin and its intended application. Shrinkage is a critical consideration in the curing process, with minimal shrinkage (2-3%) typically being the goal. For materials like concrete, curing involves the formation of silicate crosslinks, uniquely without any additives. Other organic resins might be cured with heat or specific catalysts like dibenzoyl peroxide, depending on their composition. To ensure the integrity and success of the curing process, various monitoring methods are utilized, including rheological analysis, thermal analysis, dielectrometric analysis, spectroscopic analysis, and ultrasonic analysis. These techniques collectively contribute to the precise control and optimization of the curing process.

Real-Life Applications and Scientific Insights

Understanding the practical applications and scientific nuances of fiberglass resin, epoxy resin, and other resin types can provide valuable insights for both professionals and hobbyists. Let's explore further.

Boat Building: Fiberglass resin, a blend of organic compounds, is a staple in boat construction, providing a cost-effective and semi-flexible structure. Epoxy resin, known for its high strength, is also used for high-end boats, reflecting the industry's growth.

Windmill Blades: The durability of fiberglass resin, often composed of terpenes like alpha-pinene and beta-pinene, makes it suitable for windmill blades, standing up to the elements.

Surfboards: Custom surfboard makers often mix their resin blends, using both polyester and epoxy resins to achieve the desired performance. The choice of monomers and curing methods can significantly impact the final product.

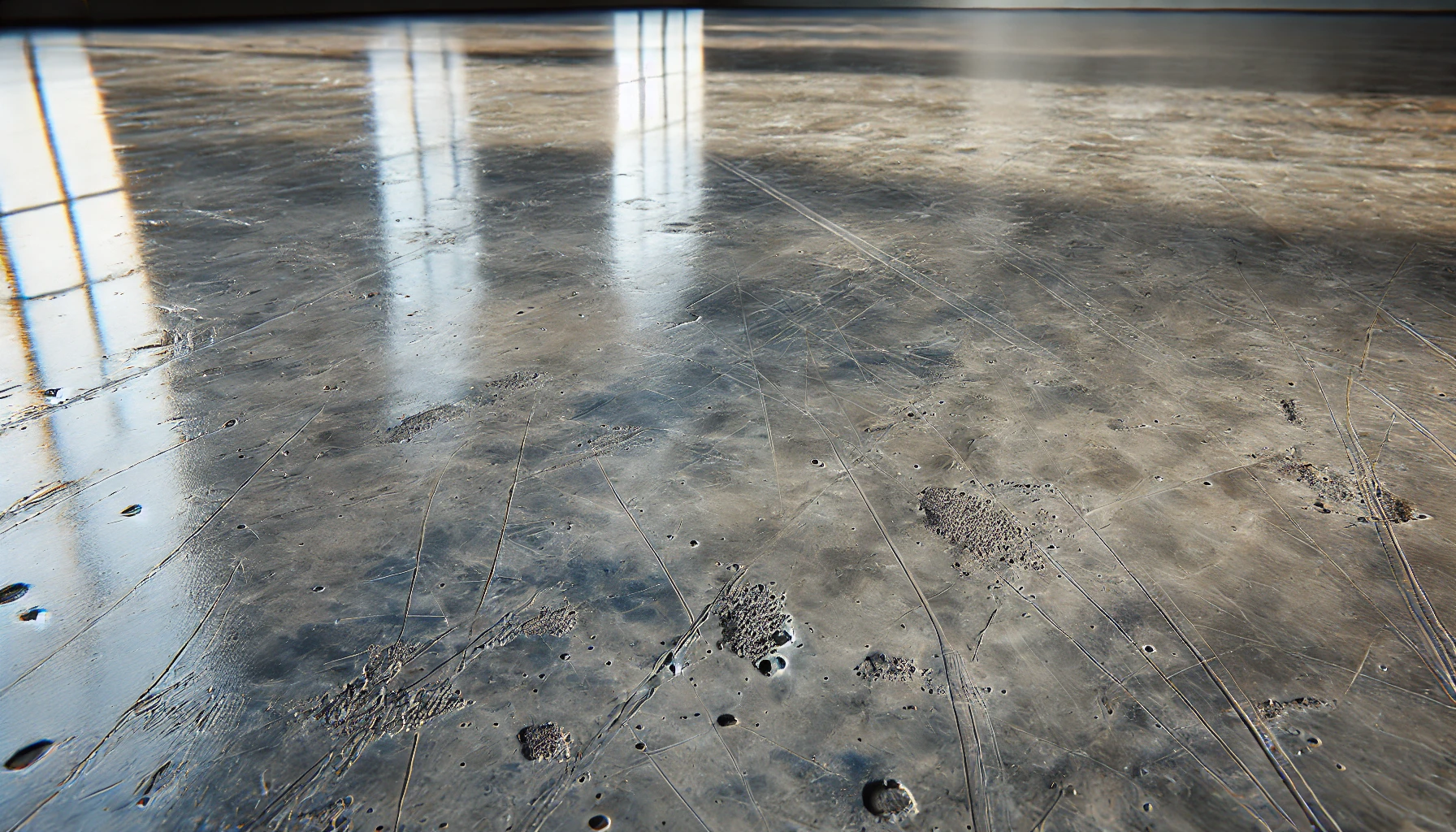

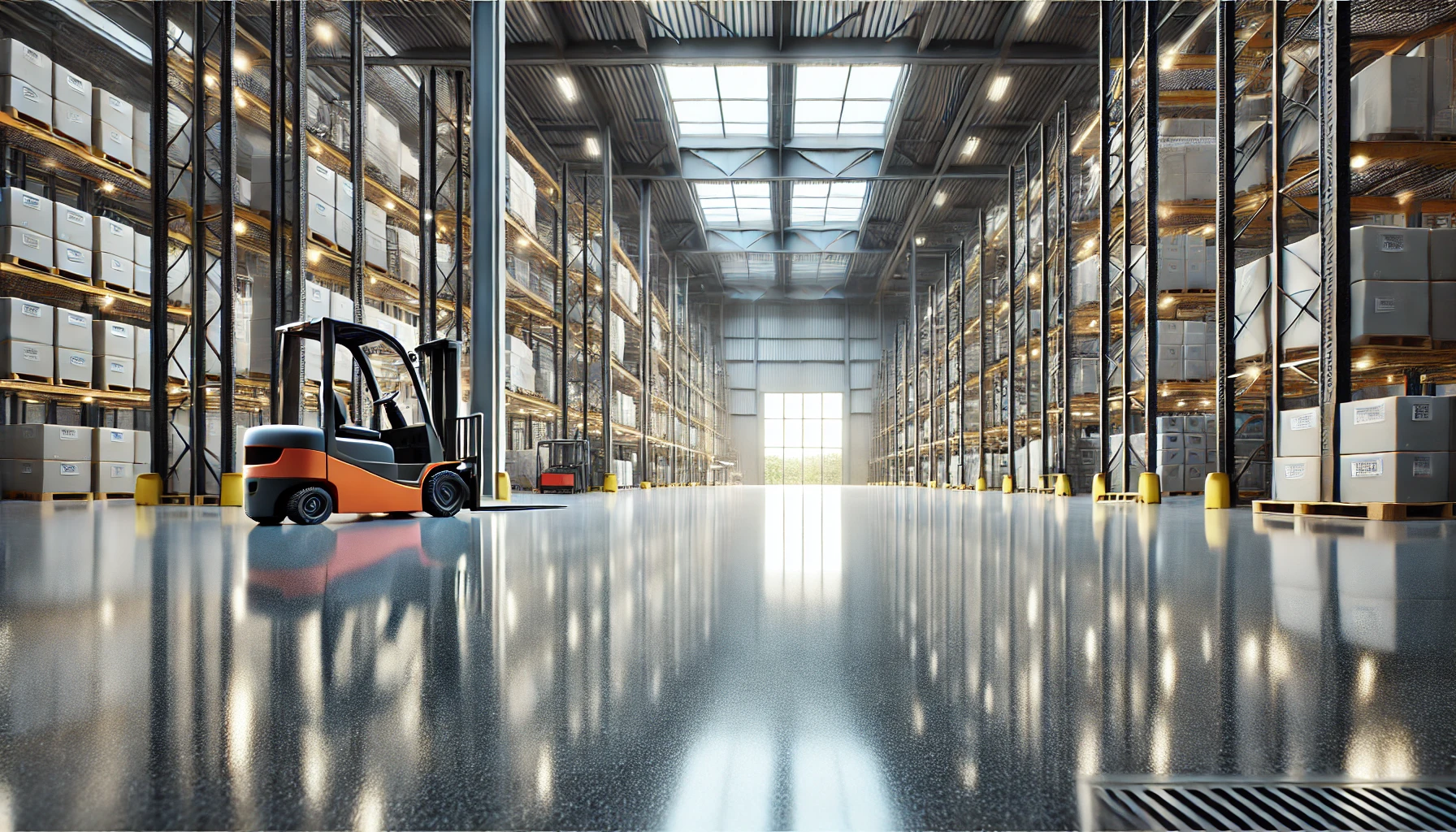

Flooring Solutions: Epoxy resin is a popular choice for industrial flooring, like the services provided by CCE, due to its strength and resistance to moisture and chemicals. This resin is often mixed with expensive additives to maintain superior properties.

Scientific Aspects

Chemical Composition: Resins consist of various monomers and additives, each contributing specific properties. Most plant resins are composed of terpenes, and the choice of monomer and curing method can significantly impact the final product. Synthetic resins, such as epoxy resin, have also been developed.

Material Evolution: The evolution from pure polyester to mixed resins like polyester/styrene or pure epoxy reflects the industry's growth and the pursuit of specific characteristics. Resins are valued for the production of varnishes, adhesives, and food glazing agents. They are also prized as raw materials for the synthesis of other organic compounds and provide constituents of perfumes.

Historical and Cultural Insights: Human use of plant resins has a very long history, documented in ancient Greece, Rome, and Egypt. These were highly prized substances, used as incense in religious rites. Modern applications include the production of varnishes, adhesives, and even flavoring in certain wines.

The exploration of resins, from their real-life applications to their scientific nuances, reveals a fascinating world of material science and engineering.

Practical Considerations

When choosing a resin for a particular project, several practical considerations must be carefully weighed to ensure the best results. Here's a seamless exploration of these factors:

Project Requirements: The specific needs of the project will significantly guide the choice of resin. Assessing factors such as strength, flexibility, or waterproofing is crucial. For instance, epoxy resin is renowned for its high strength and waterproofing capabilities, making it suitable for applications that require robust bonding and sealing.

Budget Constraints: Cost is often a determining factor in the selection of resin. Polyester resin is generally more budget-friendly, offering a cost-effective solution for many applications. On the other hand, epoxy resin, known for its superior quality, may come at a higher cost. The choice between these options often reflects a balance between budget constraints and desired performance characteristics.

Skill Level: Working with resins can be a complex process, and different types may require varying levels of skill and experience. Understanding your comfort level and the technical demands of the resin is essential. For example, epoxy resins might require precise mixing and application techniques, while polyester resins might be more forgiving for beginners.

Environmental Considerations: The odor and potential environmental impact of different resins may influence the decision, especially in sensitive environments. Some resins may contain volatile organic compounds (VOCs) that can affect air quality. Additionally, considerations related to sustainability, biodegradability, and the overall environmental footprint of the resin might play a role in the selection process.

Compliance and Regulations: Depending on the industry and location, there may be specific regulations and standards that govern the use of resins. Ensuring compliance with these rules is vital, particularly in commercial and industrial applications.

Availability and Support: The availability of the resin and the support provided by the manufacturer or supplier can also be essential factors. Some specialized resins may require ordering from specific suppliers, while others might be readily available at local stores.

Advanced Resin Techniques

The resin industry is a hotbed of innovation, constantly adapting to new challenges and opportunities. From the laboratory to the factory floor, professionals are pushing the boundaries of what's possible with resins. Custom blending is one such technique, where experts mix different resins to achieve a perfect balance of strength, flexibility, and other desired traits. This approach offers tailored solutions for specific projects, whether it's a high-performance sports car or a stunning piece of art. 3D printing with epoxy resins is another groundbreaking advancement, enabling the creation of complex designs and sturdy structures. Meanwhile, the push for environmentally friendly resins reflects a global commitment to sustainability, leading to the development of green alternatives that are as effective as they are responsible.

Industry Trends

Epoxy resin is making waves across various industries, thanks to its exceptional properties. Once confined to specialized applications like industrial flooring, it's now finding its way into aerospace, automotive, and other high-tech fields. This surge in popularity is a testament to epoxy resin's versatility and performance. But the innovation doesn't stop there. The emergence of hybrid solutions, where different resins are combined or paired with other materials, is unlocking new possibilities for creativity and functionality. These hybrid approaches are redefining what's achievable with resins, from cutting-edge architectural designs to next-generation consumer products. And as the world grapples with environmental challenges, the resin industry is stepping up, focusing on sustainable practices and eco-friendly products. This shift towards greener solutions is more than a trend; it's a fundamental transformation that aligns the industry with the broader goals of society.

Innovative Applications

Resins are being used in the medical field for devices and prosthetics, thanks to their customizable properties. This innovative application showcases the versatility and adaptability of resins in critical healthcare solutions. Artists are embracing resins, especially epoxy, to create stunning artworks and sculptures. The aesthetic qualities of resins, combined with their structural integrity, make them a popular choice for modern artistic creations. In architectural design, the aesthetic and structural qualities of resins are being leveraged in modern designs. From sleek surfaces to innovative structural components, resins are playing a vital role in shaping contemporary architecture.

Conclusion

The world of resins, encompassing fiberglass resin, epoxy resin, and more, is a dynamic and exciting field. From traditional applications like boat building and industrial flooring to cutting-edge uses in 3D printing and art, the possibilities are endless.

Understanding the science, embracing the trends, and exploring innovative applications can lead to remarkable achievements. Whether you're a seasoned professional or just starting your journey, the resin industry offers a wealth of opportunities to learn, grow, and create.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

Lets Get In Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.

We provide durable epoxy and polyaspartic flooring for garages, basements, warehouses, and commercial spaces. Serving Toronto, Vaughan, Mississauga, Markham, and beyond, we ensure fast, high-quality installations.

Epoxy Services

Contact us

Business Hours

- Mon - Sun

- -

Google Reviews

Edit Google Reviews Widget

Call

+1 647 955 6885@ 2025 All Rights Reserved || Crystal Clear Epoxy Inc