Floor Coving: The Seamless Transition | Crystal Clear Epoxy

| Section | Key Points |

|---|---|

| Introduction | Definition and relevance of floor coving in commercial and industrial settings. |

| Floor Coving Basics | Types, purpose, and benefits such as preventing dirt buildup, water containment, and regulatory requirements. |

| Floor Coving Benefits | Advantages including easier cleaning, impact damage protection, and aesthetic enhancement. |

| Integral Cove Base | Definition, characteristics, sanitary advantages, and installation considerations. |

| Installing a Mortar Cove Base | Step-by-step installation process, importance of surface preparation, and curing and sealing. |

| Cleaning Integral Floor Cove | Maintenance and cleaning procedures. |

| Choosing the Best Sanitary Protection | Considerations for specialized facilities and alternative options. |

| Conclusion | Summary of the importance and benefits of floor coving for various settings. |

| FAQs | Commonly asked questions about floor coving. |

Introduction

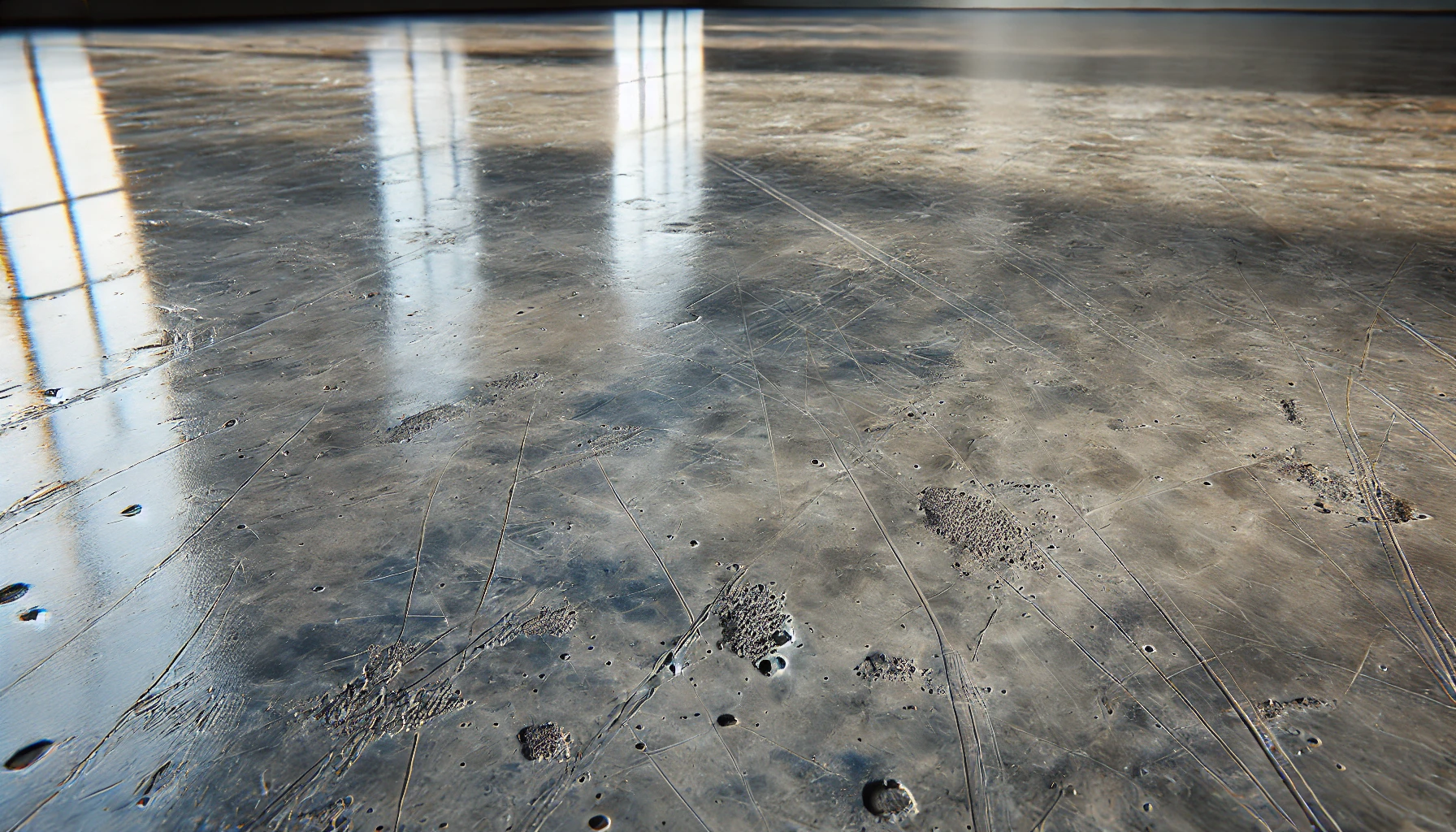

Definition of Floor Coving

Floor coving refers to the seamless transition between a room's floor and wall. This curved joining eliminates the sharp 90-degree angle, replacing it with a sloped surface. In commercial and industrial settings, epoxy coving is often the material of choice due to its durability and easy maintenance.

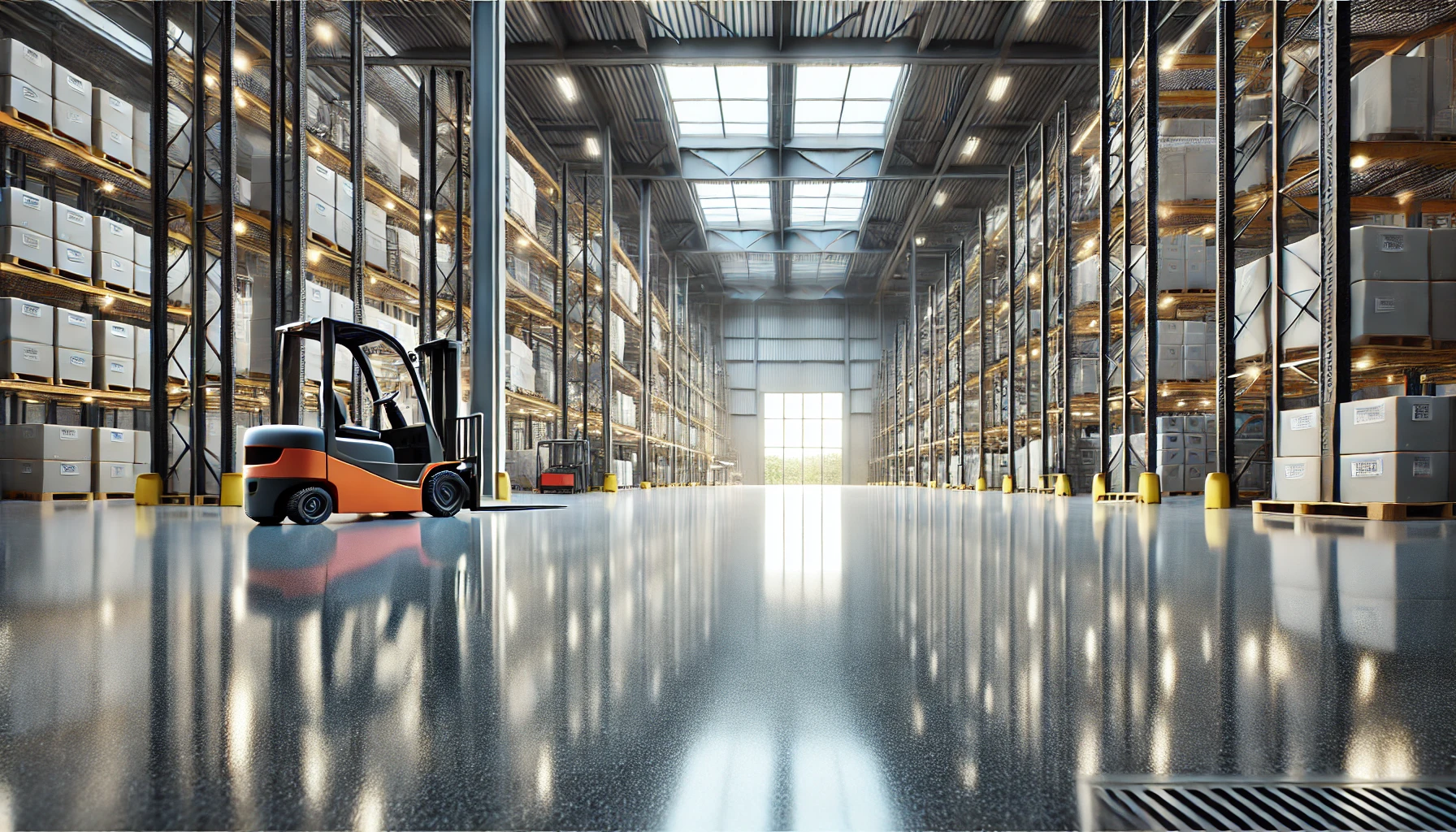

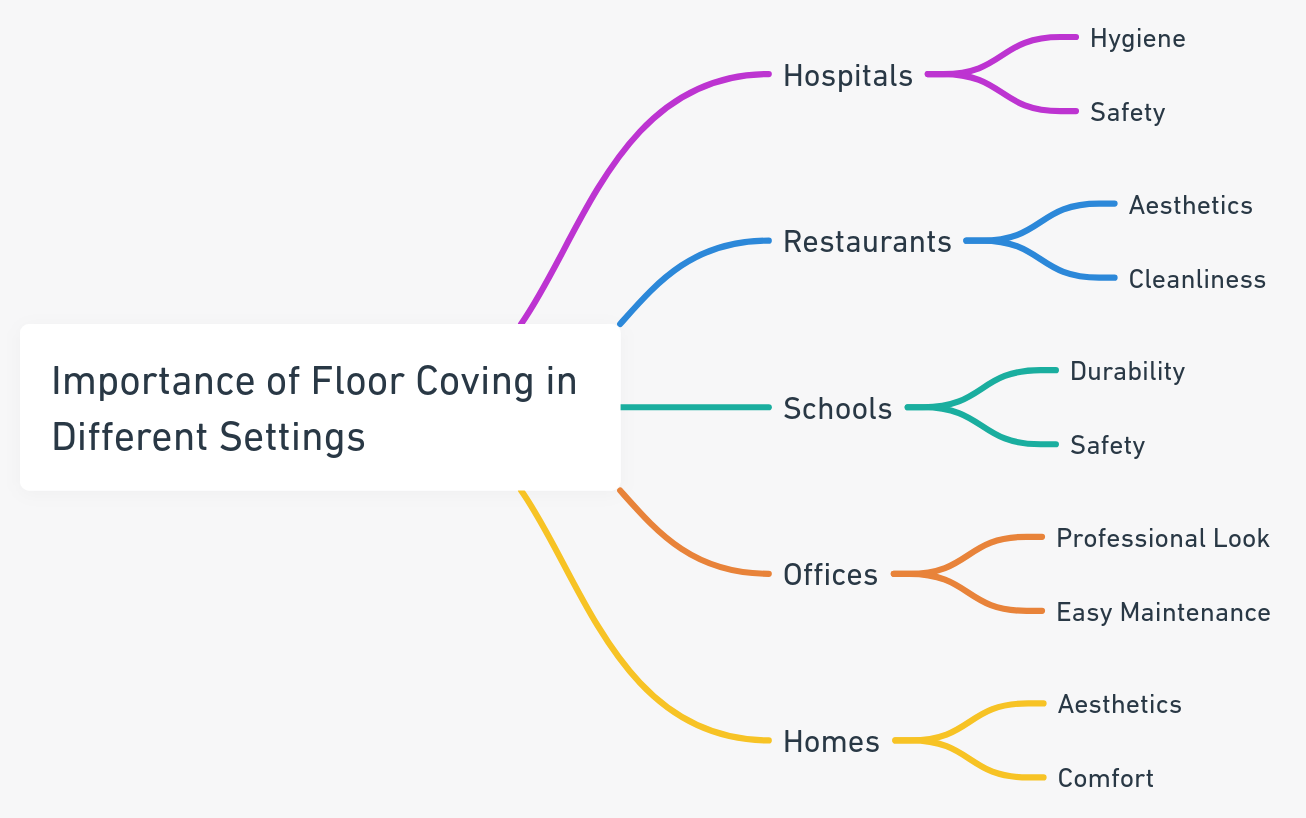

Its Relevance in Commercial and Industrial Settings

Floor coving plays an essential role in various settings such as hospitals, laboratories, and manufacturing plants, where hygiene and ease of cleaning are paramount. By eliminating corners that are hard to clean, coving contributes to maintaining a sanitary environment.

Floor Coving Basics

Types of Cove Base Categories

Residential Cove Base

In the world of interior design, residential cove bases are often the go-to choice for homeowners looking to add both aesthetic and functional elements to their living spaces. These cove bases are usually designed with a keen eye for aesthetics, offering a wide range of colors, patterns, and textures that can seamlessly blend with or accentuate the home's existing décor. The materials commonly used for residential cove bases are softer, such as vinyl or rubber, which are not only visually appealing but also relatively easy to install. While these materials offer sufficient durability for everyday household use, they may not be the best fit for environments that experience heavy foot traffic or frequent chemical exposure. Additionally, residential cove bases are generally more budget-friendly, making them an accessible option for the average homeowner.

Commercial/Industrial Cove Base

Contrastingly, commercial and industrial cove bases are engineered with a primary focus on functionality. These types of cove bases are often made from robust, durable materials like epoxy resins, which are capable of withstanding the rigors of heavy foot traffic, chemical spills, and other challenging conditions commonly found in commercial or industrial settings. In addition to their durability, these cove bases are also designed for ease of cleaning and are often resistant to bacterial growth, making them an ideal choice for healthcare facilities, food production areas, and other specialized environments. While they can be designed to be aesthetically pleasing, the range of design options is generally more limited compared to residential cove bases. Due to the specialized materials and fitting requirements, professional installation is usually recommended, adding to the overall cost. Therefore, commercial and industrial cove bases are often viewed as a long-term investment, given their higher upfront costs and durable nature.

Purpose and Benefits

1. Preventing Dirt/Debris Buildup

Coved flooring prevents the accumulation of dirt, debris, and bacteria, making cleaning more efficient.

2. Water Containment

Floor coving helps in containing spillages, thus preventing water damage to walls and subfloors.

3. Regulatory Requirements

Many industries require coved flooring to meet health and and safety standards. In healthcare settings, for instance, coved flooring is often a regulatory requirement to reduce the risk of bacterial growth and facilitate easy cleaning. Similarly, in the food and beverage industry, coving helps meet hygiene standards by minimizing areas where contaminants could gather.

Integral Cove Base

Definition and Characteristics

An integral cove base refers to a cove base formed from the same material as the floor, creating a seamless and unified surface. These are often made of epoxy resins, which are both durable and easy to clean.

Sanitary Advantages

The seamless nature of an integral cove base offers superior sanitary benefits. There are no joints or seams where bacteria and dirt can accumulate, making it an ideal choice for environments that need to maintain high levels of cleanliness.

Proper Installation and Height Considerations

The height of the cove base can vary depending on the specific needs of an environment. Generally, a taller cove base is more effective in environments that require stringent hygiene protocols. Proper installation is crucial to ensure that the cove base performs its function effectively, and Crystal Clear Epoxy Inc. specializes in ensuring a perfect fit every time.

Installing an Epoxy Mortar Cove Base

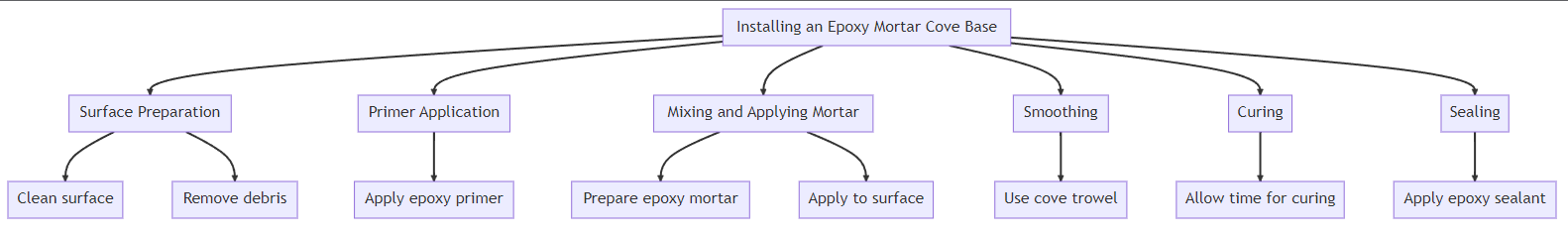

When it comes to installing an epoxy mortar cove base, the process involves several crucial steps to ensure both durability and aesthetic appeal.

Step-by-step Installation Process

Surface Preparation: The installation process begins with meticulous surface preparation. It's essential to clean the surface thoroughly, removing any debris, dust, or existing coatings to ensure optimal adhesion of the epoxy materials.

Primer Application: Once the surface is prepared, the next step is to apply a coat of epoxy primer. This primer serves as a bonding agent that enhances the adhesion between the surface and the epoxy mortar, ensuring a long-lasting installation.

Mixing and Applying Mortar: After the primer has been applied and allowed to dry, you'll need to prepare the epoxy mortar mix. This mortar is then applied to the prepared surface to form the cove base. The application should be done carefully to achieve the desired shape and thickness.

Smoothing: Following the mortar application, a cove trowel is used to smooth out the surface. This step is crucial for achieving a uniform and aesthetically pleasing cove base. It's important to work quickly but carefully, as epoxy mortar can set rapidly.

Curing: After smoothing, the epoxy mortar needs adequate time to cure. The curing time can vary depending on the specific product used, so it's important to follow the manufacturer's guidelines. During this period, the mortar hardens and bonds securely to the surface.

Sealing: The final step in the installation process is sealing the cove base. A suitable epoxy sealant is applied to provide an additional layer of protection, enhancing both the durability and appearance of the cove base.

Importance of Surface Preparation

Surface preparation is crucial for the adhesion and longevity of the cove base. Any grease, dirt, or loose material can interfere with the bonding process.

Curing and Sealing

Proper curing is essential for achieving the full strength of the epoxy material. After curing, a sealant is applied to protect against moisture and chemical exposure.

Cleaning Integral Floor Cove

Maintenance and Cleaning Procedures

Regular cleaning is essential to maintain the hygienic conditions of an integral floor cove. Simple procedures such as sweeping, mopping, and occasional deep cleaning with appropriate cleaning agents are generally sufficient.

Choosing the Best Sanitary Protection

Considerations for Specialized Facilities

For facilities like labs or clean rooms, additional considerations may include chemical resistance and static control.

Prefabricated, Polymer-Composite Curbs as an Alternative

Though epoxy is often the material of choice, prefabricated polymer-composite curbs offer a quick and easy alternative, especially for retrofitting existing facilities.

Conclusion

In summary, this article has explored the critical aspects of floor coving, from its fundamental role in commercial and industrial environments to the various types and benefits it offers. We've delved into the specific advantages of using coves, such as easier cleaning, impact damage protection, and aesthetic enhancement. The article also provided insights into the installation and maintenance procedures that ensure the longevity and effectiveness of floor coving. Whether you're in a specialized industry with strict regulatory requirements or looking for a functional and aesthetic upgrade, floor coving offers a comprehensive solution to meet a wide array of needs. As you consider the right flooring options for your facility, this information serves as a thorough guide for making an informed decision that will benefit you for years to come.