Professional Painting solutions for Industrial Spaces

Industrial painting is crucial for protecting and enhancing the surfaces of machinery, buildings, and equipment. The paint must withstand extreme conditions, and the application requires specialized knowledge. Here, we explore the paints, techniques, tools, and pros and cons of industrial painting.

Industrial Painting

Industrial painting is an essential process that serves to protect and enhance the surfaces of machinery, buildings, and equipment. Withstanding extreme conditions is a must, and applying the paint requires specialized knowledge and skills. In this context, we delve into the different types of paints used in industrial painting, the techniques, tools, and the advantages and disadvantages.

Polyurethan Paints:

Polyurethane paints are known for their exceptional weather resistance and durability. They are formulated to provide a strong coating that resists chipping, cracking, and peeling.

Application: Commonly used in heavy-duty industrial environments, these paints are applied to surfaces that need to endure harsh weather and heavy wear.

Pros: They offer excellent flexibility, gloss retention, and resistance to chemicals.

Cons: These paints can be more challenging to apply, and improper application can lead to poor performance.

Zinc-rich Primers:

Zinc-rich primers are specifically designed to provide corrosion resistance. They form a protective barrier that prevents rust from forming on metal surfaces.

Application: They are typically used on steel structures, such as bridges, tanks, and metal buildings, where corrosion resistance is vital.

Pros: Zinc-rich primers are effective in protecting against rust and provide a solid foundation for additional paint layers.

Cons: They must be applied precisely, and the surface must be adequately prepared; otherwise, the protection may be compromised.

Alkyd Paints:

Alkyd paints are known for their gloss and color retention. They form a hard, glossy surface that resists wear.

Application: Often used in industrial settings where a glossy finish is desired, such as on machinery or equipment.

Pros: These paints offer a smooth finish and maintain their appearance over time.

Cons: The longer drying times can slow down projects, and they may not be as environmentally friendly as other paint options.

Industrial Painting Installation in Ontario, Canada

Interested in having new paint installed professionally to increase the longevity of your space? Get in contact with our team to get a quote today!

Techniques and Tools for Industrial Painting Services

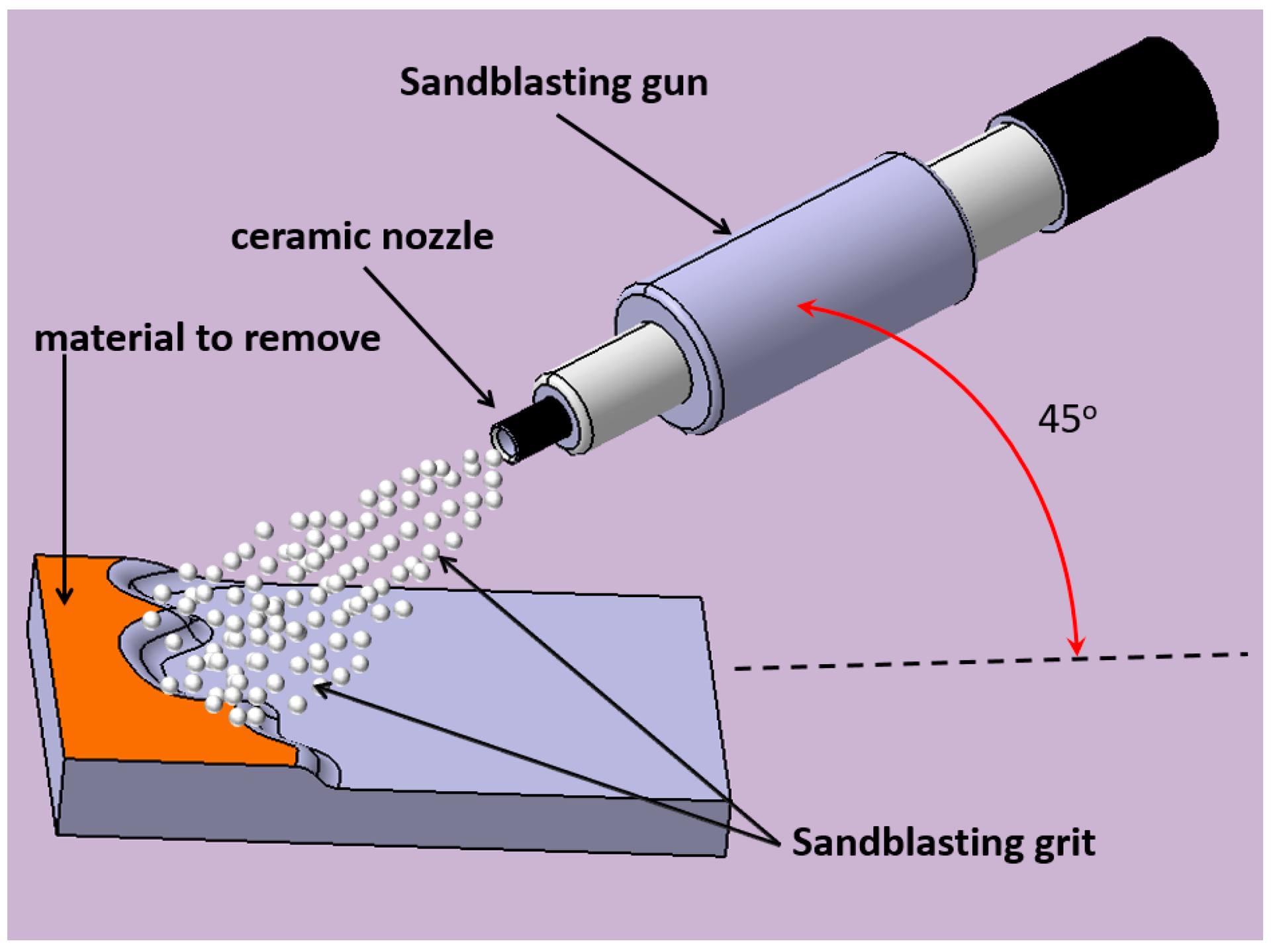

Sandblasting

Sandblasting is a process that involves forcefully propelling a stream of abrasive material against a surface. The main purposes of sandblasting are to remove rust, old paint, contaminants, and imperfections from surfaces, making them more receptive to new paint. Additionally, this technique is used to create a roughened surface that increases the adhesion of the paint. The key equipment used for sandblasting includes a blasting machine, which houses the abrasive material and controls its propulsion. An operator uses a blasting gun to direct the abrasive material precisely onto the surface. For safety, operators must wear protective gear like helmets, suits, and gloves to shield themselves from abrasive materials and flying debris. Although the process is termed 'sandblasting', various abrasives can be used. These might range from sand to steel grit, walnut shells, or even baking soda, depending on the surface's requirements and the desired finish.

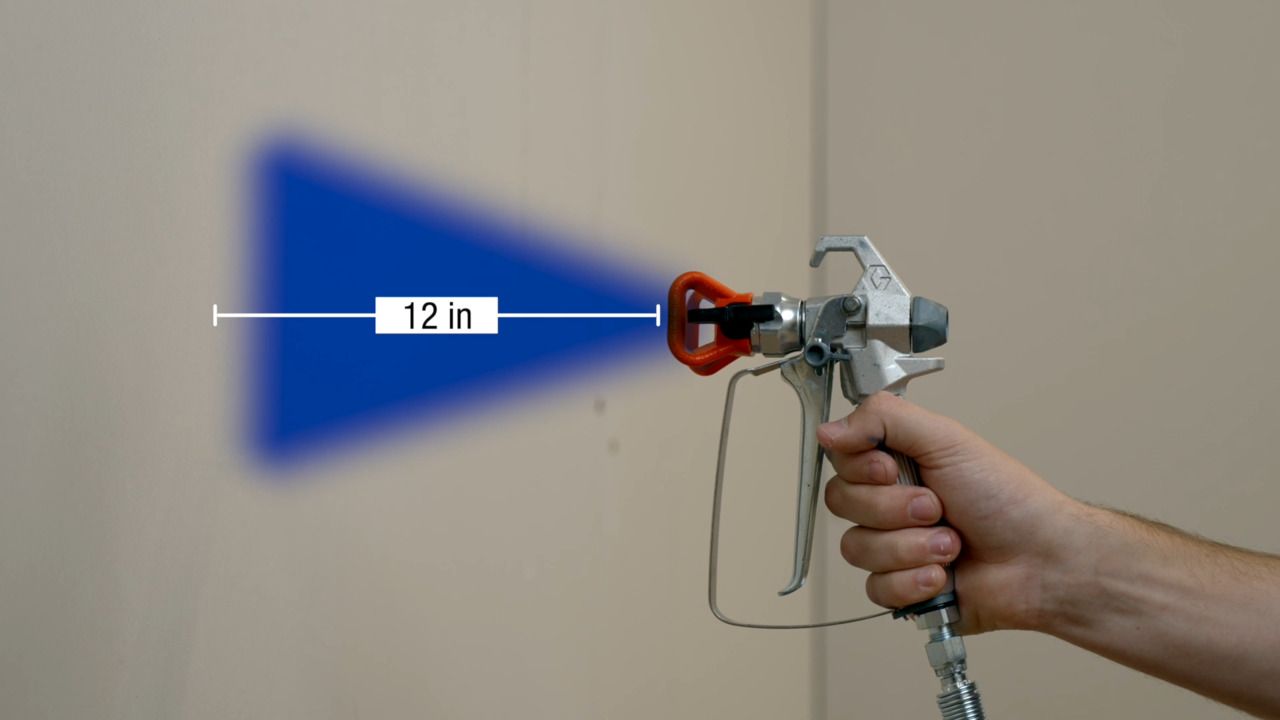

Airless Spraying

Airless spraying is a technique that utilizes a pressurized system to push paint or a coating material through a nozzle. This method produces a fine mist without the need for compressed air. This technique is highly efficient, allowing for quick coverage of large areas. One of its main advantages is that it offers a smooth finish, free from the marks typically left behind by brushes or rollers. The primary tool for airless spraying is the airless sprayer, which uses a motor to pressurize the paint and push it out. Depending on the application, various spray tips and guards can be attached to the sprayer, each offering different patterns and flow rates. A high-pressure hose is used to connect the sprayer to the spray gun. Airless spraying has several benefits, including reduced overspray, consistent paint application, and the capacity to apply thick coatings in just one pass.

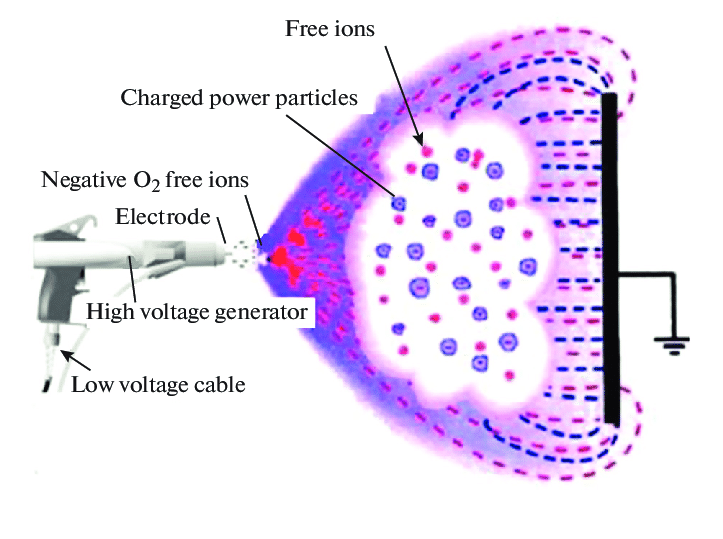

Electrostatic Painting

Electrostatic painting is a method where paint particles are charged electrically. Once charged, these particles are attracted to a grounded surface, ensuring they spread uniformly. The main advantage of this method is its ability to ensure uniform coverage. The charged particles have a natural tendency to "wrap around" surfaces, which minimizes drips and ensures an even coating. A specialized electrostatic spray gun is used for this process. It adds an electrical charge to the paint particles as they exit the gun. To make sure the object attracts these charged particles, it's connected to the ground using a grounding wire. Electrostatic painting is especially valuable when dealing with complex shapes. Not only does it provide an even coat, but it also significantly reduces the amount of paint required due to decreased overspray.

We provide durable epoxy and polyaspartic flooring for garages, basements, warehouses, and commercial spaces. Serving Toronto, Vaughan, Mississauga, Markham, and beyond, we ensure fast, high-quality installations.

Epoxy Services

Contact us

Business Hours

- Mon - Sun

- -

Google Reviews

Edit Google Reviews Widget

Call

+1 647 955 6885@ 2025 All Rights Reserved || Crystal Clear Epoxy Inc