Polyurethane Paint in Industrial Applications: A Specialist's Guide

Polyurethane paint is an incredibly versatile and advanced coating material that has become indispensable in industrial applications. It's a result of both art and science, formulated to provide a balance of aesthetics, protection, and durability. Here's an exhaustive guide, diving into the intricacies of polyurethane painting solutions.

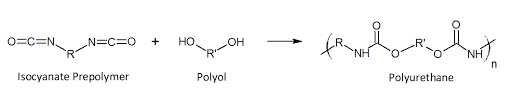

Composition and Chemistry

Polyurethane paint is formulated from a reaction between polyols and polyisocyanates. The result is a polymer structure that can be modified to provide specific characteristics such as elasticity, hardness, or gloss level. The formulations are carefully crafted to provide specific attributes, depending on the type, whether it's water-based, solvent-based, or high-solids polyurethane.

Polyurethan Painting Installation for Industrial Spaces in Ontario

Interested in Having Polyurethane installed professionally? Get in contact with our team to get a quote today!

Versatility in Application

The adaptability of polyurethane paint is one of its standout features. It can be used across a wide spectrum of industries, from automotive and marine to construction and furniture. Its strong adherence to various substrates, including metals, plastics, and wood, makes it a favored choice. Whether you're aiming for a glossy showroom finish or a robust protective layer for outdoor machinery, polyurethane paint fits the bill.

Toughness and Durability

Polyurethane paints are renowned for their resistance to abrasion, corrosion, UV rays, and chemicals. They form a barrier that is incredibly hard yet maintains a level of flexibility that prevents cracking and peeling. On wood, polyurethane provides a resilient layer that preserves the beauty and integrity of the surface for many years, often exceeding a decade with proper care.

Customizable Features

The formulations can be tailored to achieve different finishes, textures, and color options. From matte to high-gloss finishes, polyurethane coatings can be crafted to exact specifications. The mixing ratios can vary, but a common ratio is 2:1 or 3:1 of paint to hardener, with a percentage of thinner, depending on the application method and desired finish.

Application Techniques

The application of polyurethane paint requires expertise and attention to detail. Surface preparation is key, involving thorough cleaning, priming, and possible sealing of the surface. Applying thin, even coats using brushes, rollers, or specialized sprayers ensures a smooth finish. Sanding between coats with fine-grit sandpaper enhances adhesion and smoothness. A typical application might require 3-4 coats, and proper curing time, which can take up to a week, ensures the paint reaches its full potential in hardness and durability.

Comparing with Other Materials

In comparison to other coatings like epoxy or acrylic, polyurethane stands out in various aspects. While epoxy may offer higher chemical resistance, polyurethane has better flexibility and UV resistance. Acrylic may be easier to apply, but polyurethane typically offers better overall durability and resilience.

Limitations and Considerations

Despite its many advantages, there are considerations to keep in mind. Polyurethane can yellow over time, especially when exposed to sunlight. Its application can be complex and requires proper safety precautions due to potential toxicity, especially with solvent-based versions. Understanding when not to use polyurethane is equally important, such as in applications that require a softer finish or increased breathability.

Conclusion

Polyurethane paint stands as a beacon of innovation and functionality in the world of industrial coatings. Its unique combination of toughness, versatility, and aesthetic appeal makes it an unparalleled choice for a wide array of industrial applications. Whether you are a seasoned professional in the coating industry or exploring options for your next big project, polyurethane offers a multifaceted solution that can be tailored to meet the most exacting standards.

With careful consideration of specifications, application methods, and potential drawbacks, polyurethane paint is not just a product but a powerful tool in the hands of industry experts. Its legacy and continued evolution bear testimony to the material's pivotal role in shaping the industrial landscape.