Electrostatic Discharge (ESD) Flooring Systems

Get Your Quote Now

Contact Us

We will get back to you as soon as possible.

Please try again later.

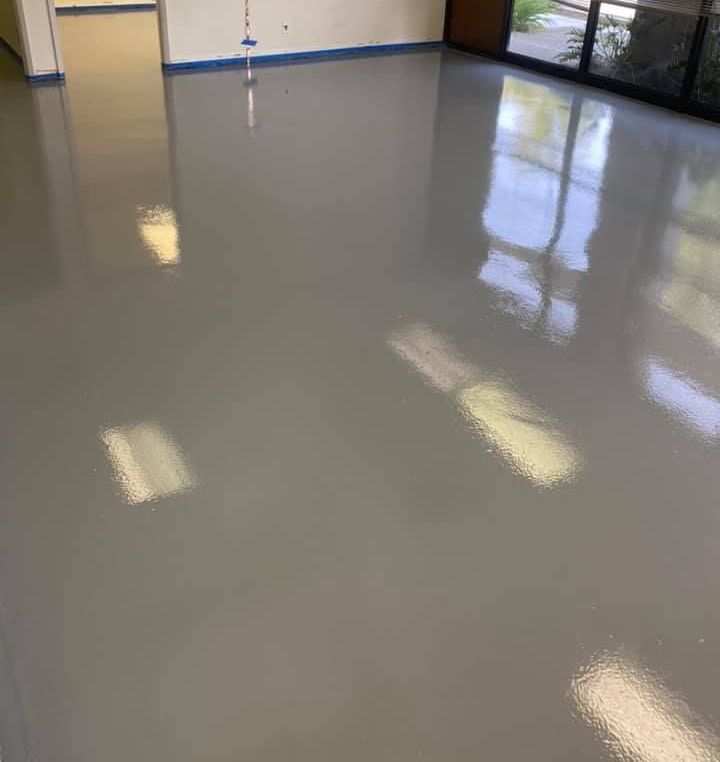

Epoxy floor ESD systems are vital in environments where controlling electrostatic discharge is crucial. These systems are designed to prevent the buildup and sudden discharge of static electricity, which can damage sensitive electronic components or even ignite flammable substances. Epoxy flooring plays a key role in these systems by providing a seamless, durable, and easily maintainable surface that integrates conductive materials to dissipate static charges safely.

Advantages of Epoxy ESD Flooring

- Prevents damage to sensitive electronic equipment and components.

- Reduces the risk of explosions in flammable environments.

- Meets industry standards and regulations for ESD protection.

Applications of Epoxy ESD Flooring

Electronics Manufacturing

Protecting delicate electronic components during assembly and testing is crucial, particularly in industries such as semiconductor manufacturing, aerospace, and defense. These sectors require stringent measures to ensure the integrity and functionality of their sensitive electronic parts, thereby maintaining high standards of quality and reliability.

Healthcare Facilities

Safeguarding sensitive medical equipment and ensuring a sterile environment is essential, particularly in areas such as laboratories, clean rooms, and operating theaters. These settings demand stringent measures to maintain the integrity and sterility of medical instruments, thereby ensuring patient safety and the accuracy of medical procedures.

Chemical Processing Plants

Preventing static build-up that could ignite flammable chemicals is critical in areas such as mixing rooms, storage areas, and processing lines. These environments require stringent control measures to ensure safety and prevent potential hazards associated with static electricity and flammable substances.

Compliance and Certification

Industry Standards

ANSI/ESD S20.20: This standard provides guidelines for the development of an ESD control program to protect electronic parts, assemblies, and equipment susceptible to electrostatic discharge.

IEC 61340-5-1: This international standard specifies the requirements for establishing an ESD control program to protect electrostatic discharge-sensitive devices.

Importance of Certifications

Businesses in Ontario and Canada that handle ESD-sensitive equipment, such as electronics manufacturers, telecommunications companies, and healthcare providers, must implement these standards to comply with industry regulations and protect sensitive components from ESD damage.

Organizations often seek certification to demonstrate compliance with these standards. Certification involves a thorough audit by a third-party organization to ensure that the ESD control program meets all requirements set forth by ANSI/ESD S20.20 or IEC 61340-5-1.

Frequently Asked Covebase Questions

How does epoxy ESD flooring work?

Epoxy ESD flooring incorporates conductive materials within the epoxy resin that help to safely dissipate static charges away from sensitive areas, ensuring static control and protection.

What maintenance is required for epoxy ESD flooring?

Regular cleaning with appropriate cleaners, periodic inspections, and prompt repairs of any damage are essential to maintain the flooring’s ESD properties and overall condition.

How does epoxy ESD flooring compare to other types of ESD flooring?

Epoxy ESD flooring offers superior durability, ease of maintenance, and a seamless finish compared to other ESD flooring types such as vinyl or tile.

We provide durable epoxy and polyaspartic flooring for garages, basements, warehouses, and commercial spaces. Serving Toronto, Vaughan, Mississauga, Markham, and beyond, we ensure fast, high-quality installations.

Epoxy Services

Contact us

Business Hours

- Mon - Sun

- -

Google Reviews

Edit Google Reviews Widget

Call

+1 647 955 6885@ 2025 All Rights Reserved || Crystal Clear Epoxy Inc