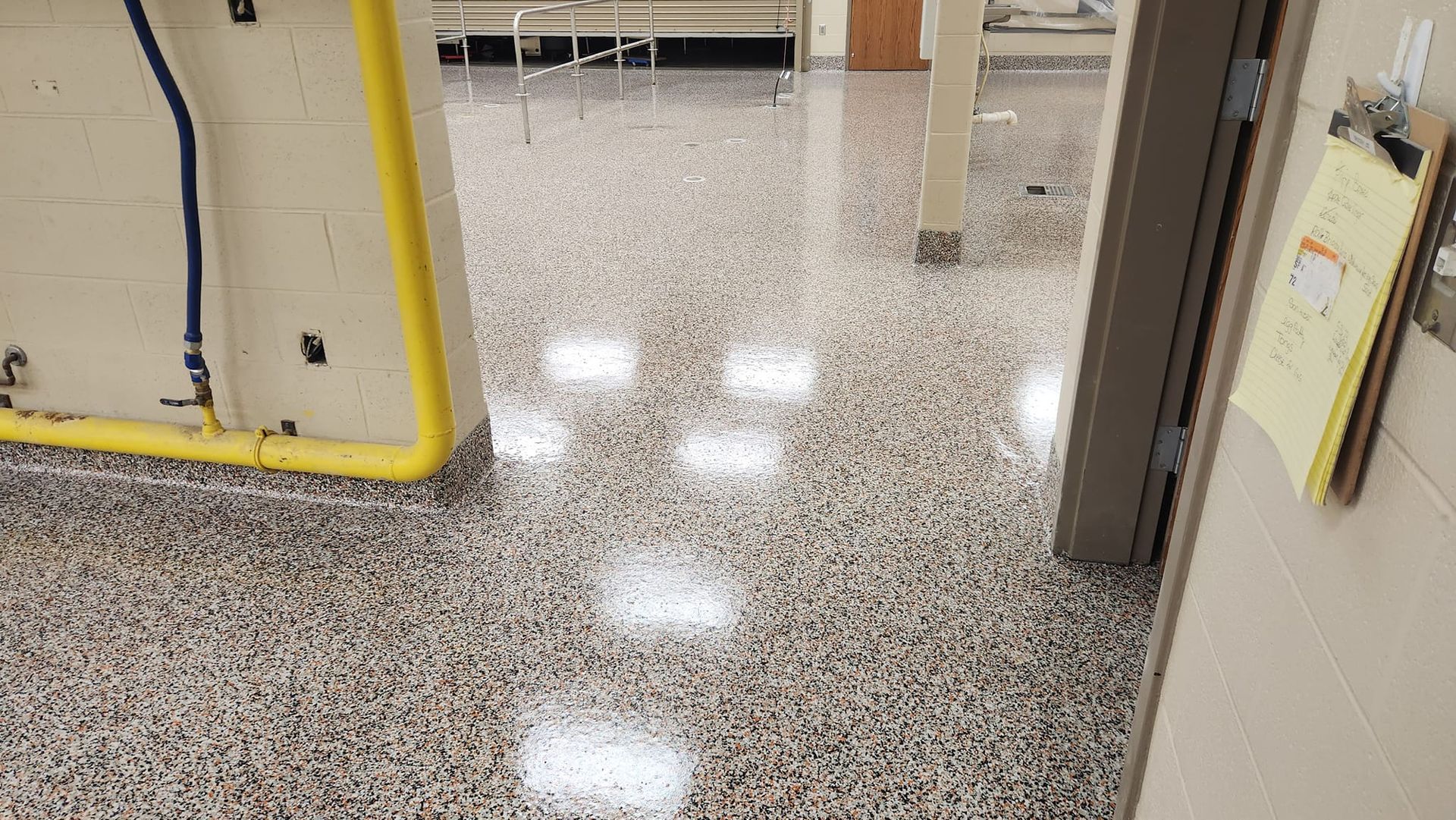

Antimicrobial Epoxy Flooring System

In today's world, maintaining hygienic environments is crucial, especially in industries like healthcare, food processing, and pharmaceuticals. Antimicrobial epoxy flooring has emerged as a game-changing solution, offering unparalleled protection against harmful microorganisms.

Get Your Quote Now

Contact Us

We will get back to you as soon as possible.

Please try again later.

Antimicrobial epoxy flooring is an essential solution, specifically designed to inhibit the growth of harmful microorganisms like bacteria, mold, and fungi. This type of flooring not only ensures a cleaner environment but also helps to reduce the risk of contamination and the spread of disease, making it a vital component in facilities requiring the highest standards of sanitation.

Advantages of Antimicrobial Epoxy Flooring

Antimicrobial epoxy flooring provides a seamless, non-porous surface that resists moisture and prevents the harboring of pathogens. Its durability and resistance to harsh chemicals and frequent cleaning protocols make it an ideal choice for high-traffic areas that must remain sterile. Whether in a hospital operating room or a food processing plant, antimicrobial epoxy flooring offers a reliable, long-term solution for maintaining health and safety standards.

Key Benefits

- Inhibits Microorganism Growth: Provides continuous protection against bacteria, mold, and fungi.

- Seamless and Non-Porous: Prevents the harboring of pathogens and is easy to clean.

- Durability: Stands up to heavy traffic and harsh cleaning chemicals.

- Cost-Effective: Reduces maintenance costs and enhances the lifespan of flooring in sanitary environments.

- Enhances overall hygiene in critical environments

Types of Security Lines

Solid lines: Continuous, unbroken lines used for definitive boundaries or strict separations.

Dashed lines: Intermittent markings often used to indicate flexible boundaries or temporary divisions.

Textured lines: Lines with raised or embossed surfaces that provide both visual and tactile feedback.

Glow-in-the-dark lines: Photoluminescent markings that remain visible in low-light conditions or power outages.

Applications of Antimicrobial Floors

Antimicrobial epoxy flooring is versatile and essential across various industries where hygiene is a top priority. Here's how it serves key sectors:

- Healthcare: In hospitals, clinics, and laboratories, antimicrobial epoxy flooring helps prevent the spread of infections by providing a sterile surface that is easy to clean and resistant to harsh disinfectants. It's particularly beneficial in areas like operating rooms, patient wards, and pharmaceutical labs where contamination can have severe consequences.

- Food Processing: In food and beverage production facilities, maintaining cleanliness is critical to prevent foodborne illnesses. Antimicrobial epoxy flooring ensures that bacteria and mold do not have a chance to thrive on surfaces, helping to meet regulatory standards and maintain product safety. It's perfect for areas such as kitchens, processing lines, and storage areas.

- Pharmaceuticals: In drug manufacturing plants, contamination must be avoided at all costs. Antimicrobial epoxy flooring contributes to maintaining a controlled environment that meets stringent cleanliness requirements. ensuring the purity and safety of pharmaceutical products.

- Education and Childcare: In schools and daycare centers, where children are particularly vulnerable to infections, antimicrobial flooring helps keep the environment safe by reducing the spread of germs.

- Commercial Kitchens and Restaurants: In commercial food preparation areas, antimicrobial epoxy flooring supports health and safety compliance by preventing microbial growth on surfaces exposed to food residues and moisture.

Advantages of Antimicrobial Flooring

Antimicrobial epoxy flooring offers a range of benefits that make it an ideal choice for environments requiring stringent hygiene standards. One of its most significant advantages is the long-term protection it provides. Unlike surface coatings, the antimicrobial agents are embedded throughout the entire epoxy layer, ensuring continuous protection against bacteria, mold, and fungi that doesn't wear off over time. This flooring is also highly resistant to a variety of harsh chemicals, including strong disinfectants and cleaning agents, making it suitable for environments that require frequent and rigorous cleaning protocols.

Maintenance of antimicrobial epoxy flooring is remarkably easy due to its seamless, non-porous nature. This characteristic prevents dirt, grime, and pathogens from penetrating the surface, not only making the floor easier to clean but also reducing the time and effort required for maintenance. As a result, facilities can expect lower overall upkeep costs. Additionally, epoxy flooring is renowned for its toughness and durability. It can withstand heavy foot traffic, impacts, and abrasions without deteriorating, making it a cost-effective solution that extends the lifespan of flooring in high-traffic areas.

Beyond its practical benefits, antimicrobial epoxy flooring enhances safety by preventing microbial growth, thereby reducing the risk of infections and contamination. This contributes to a safer environment for both employees and customers. Lastly, this flooring solution doesn't compromise on aesthetics. Available in a variety of colors and finishes, antimicrobial epoxy flooring not only serves a functional purpose but can also enhance the visual appeal of a facility, creating a clean and professional appearance. These combined benefits make antimicrobial epoxy flooring an excellent choice for facilities where hygiene, durability, and appearance are paramount concerns.

Comparison with Other Flooring Options

When selecting the best fleering for environments that require high levels of sanitation, It's essential to compare antimicrobial epoxy flooring with other common options. Here's how it measures up:

- Epoxy vs. Vinyl Flooring: While vinyl is a popular choice for many facilities due to its cost-effectiveness and ease of installation, it falls short in durability and resistance to chemicals and impacts. Antimicrobial epoxy flooring, on the other hand, offers superior protection against microorganisms and can withstand harsher conditions, making it a more reliable long-term investment.

- Epoxy vs. Tile Flooring: Tile flooring is another common choice, but it has grout lines that can harbor bacteria and are more difficult to clean thoroughly. Antimicrobial epoxy flooring is seamless, eliminating these potential problem areas and providing a completely non-porous surface that is much easier to maintain.

- Antimicrobial Epoxy vs. Traditional Epoxy Flooring: While traditional epoxy flooring is durable and resistant to many types of damage, it lacks the built-in antimicrobial properties that make specialized antimicrobial epoxy flooring a must-have in environments where cleanliness is critical. The added antimicrobial agents in epoxy flooring provide continuous protection, making it a better choice for healthcare, food processing, and similar industries.

- Cost-Benefit Analysis: Though antimicrobial epoxy flooring may have a higher upfront cost compared to some alternatives, its long-term benefits, including reduced maintenance costs, enhanced durability, and improved safety, make it a more cost-effective solution over time.

Compliance and Certifications

Ensuring that antimicrobial epoxy flooring meets the necessary regulatory standards is crucial for industries where hygiene and safety are paramount. Here’s a list of relevant certifications and standards that this type of flooring adheres to.

- USDA (United States Department of Agriculture): Ensures that the flooring meets hygiene and safety standards for food-related industries.

- FDA (Food and Drug Administration): Regulates flooring in environments where food and pharmaceuticals are produced, ensuring compliance with strict health standards.

- HACCP (Hazard Analysis and Critical Control Points): A systematic approach to food safety that addresses potential hazards in production processes. Flooring that meets HACCP standards helps prevent contamination.

- CFIA (Canadian Food Inspection Agency): Enforces food safety standards in Canada, ensuring that flooring in food establishments meets national regulations.

- NSF (National Sanitation Foundation): Certifies flooring materials for food safety and sanitation, verifying that they do not contribute to the growth of harmful microorganisms.

- ISO 22196: An international standard for measuring antimicrobial activity on plastics and non-porous surfaces, applicable across various industries including healthcare and food processing.

- Health Canada: Oversees compliance with safety regulations for flooring used in health and pharmaceutical environments in Canada.

- CGMP (Current Good Manufacturing Practice): U.S. and Canadian regulations that ensure products, including flooring materials, are consistently produced and controlled according to quality standards.

These certifications and standards ensure that our antimicrobial epoxy flooring complies with the stringent regulatory requirements necessary for maintaining sanitary environments in industries like healthcare, food processing, and pharmaceuticals.

Frequently Asked Antimicrobial Epoxy Questions

How long does antimicrobial epoxy flooring last?

With proper maintenance, antimicrobial epoxy flooring can last 10-20 years, depending on the environment and traffic.

Is antimicrobial epoxy flooring safe for food production areas?

Yes, it is designed to meet stringent food safety standards like HACCP, making it safe for food processing environments.

What maintenance is required?

Regular cleaning with non-abrasive, pH-neutral cleaners is recommended to maintain the flooring’s antimicrobial properties and appearance.

Can antimicrobial properties wear off over time?

No, the antimicrobial agents are integrated into the epoxy, ensuring long-lasting protection throughout the floor’s lifespan.

Is it suitable for high-traffic areas?

Absolutely, antimicrobial epoxy flooring is highly durable and designed to withstand heavy foot and equipment traffic.

Is antimicrobial epoxy flooring available in different colorus and finishes?

Yes, antimicrobial epoxy flooring comes in a variety of colours and finishes, allowing for customization to match the aesthetics of your facility.

What is the curing time for antimicrobial epoxy flooring?

Curing time can vary depending on the environment and thickness of the application, but generally, it takes 24 to 72 hours for the flooring to fully cure.

How does antimicrobial epoxy flooring handle temperature fluctuations?

Antimicrobial epoxy flooring is engineered to withstand a wide range of temperature fluctuations without compromising its integrity or antimicrobial properties. In cold storage areas, it resists cracking and maintains its seamless surface even at sub-zero temperatures. In high-temperature environments, such as industrial kitchens or manufacturing plants, the flooring remains stable and does not soften or warp. This durability makes it suitable for both extreme cold and heat, ensuring consistent performance in various conditions. Additionally, the flooring’s thermal expansion properties allow it to expand and contract with temperature changes, preventing delamination or damage over time.

We provide durable epoxy and polyaspartic flooring for garages, basements, warehouses, and commercial spaces. Serving Toronto, Vaughan, Mississauga, Markham, and beyond, we ensure fast, high-quality installations.

Epoxy Services

Contact us

Business Hours

- Mon - Sun

- -

Google Reviews

Edit Google Reviews Widget

Call

+1 647 955 6885@ 2025 All Rights Reserved || Crystal Clear Epoxy Inc